A1A Lift Planners of the Year

A1A Software LLC has announced the winners of its 2021 Lift Plan of the Year Competition.

The awards program is for companies that use A1A Software’s 3D Lift Plan as a sales tool, for bid proposals, crane selection and setup, lift planning, and documentation. Project submissions were for jobs that were completed last year.

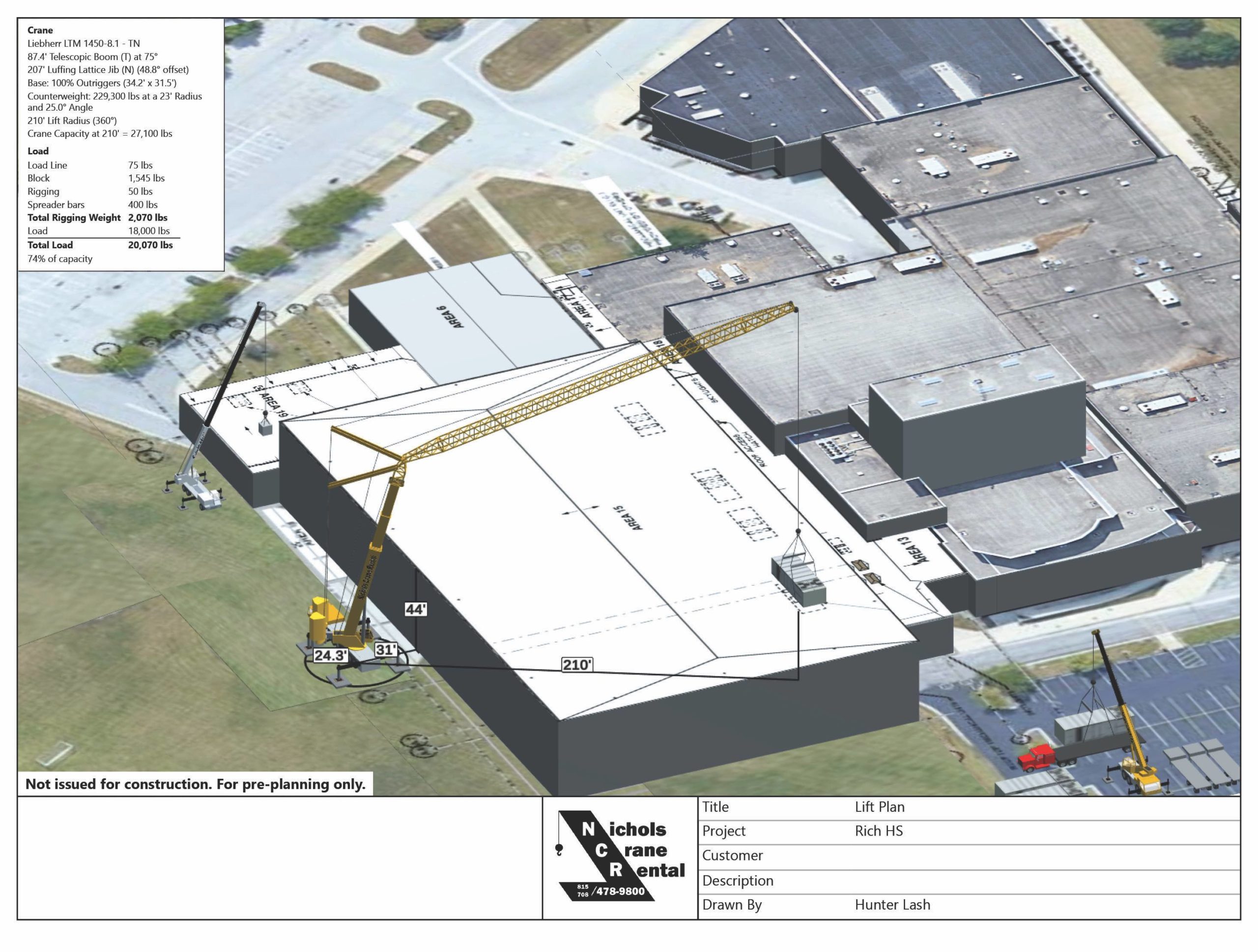

First place went to Hunter Lash, Nichols Crane Rental, Joliet, Ill.; second place was awarded to Riley Pettrone, La Grange Crane Service, La Grange, Ill.; and Brent Genseke, Rockford, Ill.-based Area Erectors received third place.

Eight entries were selected as finalists, then voting was opened to the public. “The competition focuses on the creative and practical use of 3D Lift plan to solve jobsite challenges,” said Tawnia Weiss, President of A1A Software.

- “Features and capabilities of 3D Lift Plan are constantly evolving, and its interesting to these tools applied to real projects.”

First place winner, Lash, used 3D Lift Plan in the pre planning stages of a new fieldhouse for Rich South High School to ensure efficiency, coordination with other contractors and trades, and jobsite safety. After experiencing delays due to covid-19, the contractors on this job had to work simultaneously in order to complete the project in a timely manner. This resulted in congestion on the site which meant the original lift plan was no longer an option.

“3D Lift Plan allowed us to quickly lay out a new plan and to visually show these changes,” said Lash. “We had used a combination of Google Earth images, drone footage, and site plans to accurately depict the site. The lift plan showed the build and laydown of the crane, unit staging area and swing radius of the crane. This allowed everyone to visualize what would happen on the job site and align on how the various moving parts would work together,” he continued.

First place went to Hunter Lash, Nichols Crane Rental, Joliet, Ill.

Pettrone, who received second place, used 3D Lift Plan to successfully bid on a project for the Las Campanas Observatory’s new Giant Magellan Telescope. La Grange Crane was challenged to hoist the steel super-loads through proportionately impossible roof openings on each side of the structure. The building was enclosed prior to the lift to protect the precious materials that come with telescope production.

“3D Lift Plan’s unique ability to aggregate an entire fleet’s crane configurations for max-machine utilization landed La Grange Crane the job,” said Pettrone. “3D Lift Plan helped us figure out which crane was the best for the job.” Ultimately, they decided to use a 550-ton Liebherr LTM 1450-8.1 with luffing jib.

Third place winner, Genseke, utilized 3D Lift Plan from the start of the bidding process all the way through the project until the last pieces were set on the Pritzker Military Archives Center. Two sets of three cranes lifting in tandem were required to lift each of two 250 ft long trusses with a seventh crane used for hoisting tie-in members on the steel erection. Genseke used 3D Lift Plan to provide a visual aspect of how all of these cranes would work in unison to get the job done.

“3D Lift Plan gave us the ability to show a myriad of information depending on what we wanted. We could easily show crane positions, available space on the ground for movement of the seventh crane between the truss cranes, swing radii, etc.,” said Genseke. “Without a visual representation of these steps, it would have been near impossible to explain how these large machines were going to work together.”

The remaining finalists were:

- Adrian Pasma, Sterling Crane, Edmonton, Alberta, Canada.

- Ben Cork, Beenleigh Steel Fabrications, Crestmead, Australia.

- Daniel Franco, Bay, LTD Corpus Christi, Texas.

- Jared Marcotte, Iron Stag Crane Service, Thomasville, Penn.

- Trevor Morgan, Eagle West Crane & Rigging, Abbotsford, British Columbia.