AutomationDirect Chooses TGW Logistics

AutomationDirect, an automation components and industrial control products supplier, has chosen TGW Logistics to further automate its Cumming, Georgia warehouse. By adding FlashPick and expanding pallet storage, AutomationDirect will be able to easily handle its sales and SKU growth and continue to provide fast two-day shipping for customers.

Back in 2019, AutomationDirect worked with TGW Logistics to implement mini-load and pallet crane aisles for powerful receiving and storage. Now that their sales and SKU counts have grown, and with eyes on the next 10 years of projected growth, AutomationDirect needed to further automate their operations.

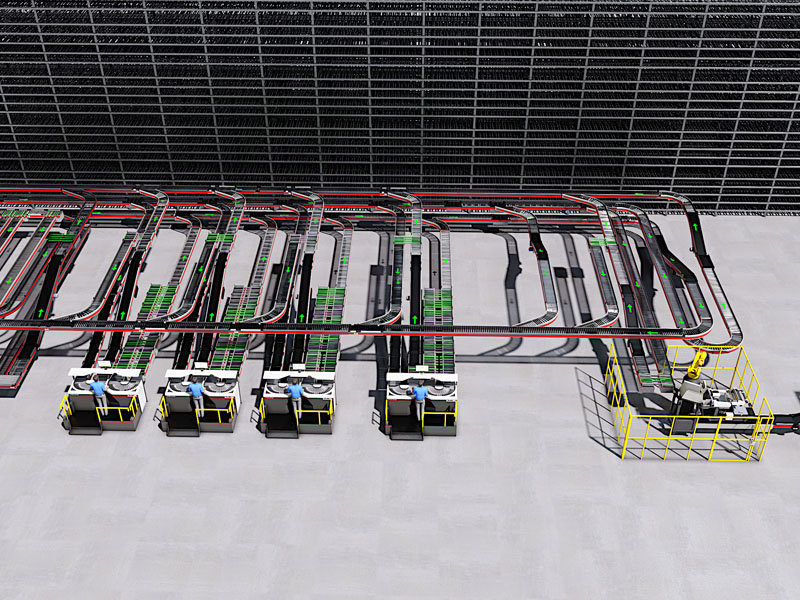

A FlashPick system for fast and accurate goods-to-person order fulfillment.

This time around, TGW Logistics will be implementing a FlashPick system for fast and accurate goods-to-person order fulfillment.

This addition will connect to the existing mini-load aisles being used for storage. Comprised of two Stingray shuttle aisles and four ergonomic PickCenter One workstations, the automation will allow AutomationDirect to meet increasing sales demand, handle future SKU growth, and maintain their two-day shipping promise—all within one eight-hour daily shift.

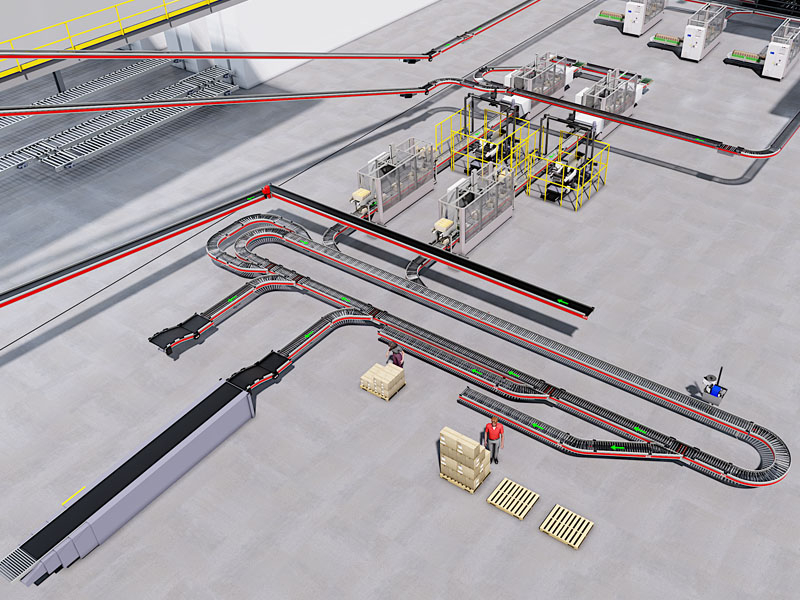

Concurrently, TGW Logistics will be expanding AutomationDirect’s pallet inventory by installing another pallet crane aisle and conveyor to support the movement of pallets in and out of the area. This was a planned expansion from the work done in 2019.

Together, the two-fold solution not only optimizes the distribution center’s fulfillment and pallet handling operations, it improves the facility’s footprint, such that there is room for future phases that could more than double the automation and throughput.

Another key component of the solution is the inclusion of TGW Logistics warehouse software: WERX. The software will take over from existing systems, orchestrating both the current automation in the building and the new FlashPick, pallet crane, and conveyor. Critically for AutomationDirect, WERX will manage cycle counts and generate and execute replenishment activities between the inbound mini-loads and order fulfillment shuttles during non-picking hours, preventing potential delays or stoppages and optimizing picking time.

Comprised of two Stingray shuttle aisles and four ergonomic PickCenter One workstations, the automation will allow AutomationDirect to meet increasing sales demand.

AutomationDirect has entrusted TGW Logistics for warehouse automation since 2013. Across multiple warehouses, TGW and AutomationDirect have worked together to automate various key processes, always with an eye on future business needs.

Mark Hermann, Logistics Team Captain at AutomationDirect, says of the relationship, “TGW Logistics continues to prove themselves, not only with their technology, but with their ability to develop automation solutions that fit our current needs and future growth.”

- The automation solution will be implemented during ongoing operations and is expected to go live in August 2026.