cromox Chain Hoist, Trolley

Ketten Wälder GmbH has increased global stock of its cromox-branded stainless steel chain hoist and trolley, manufactured in Bad Endorf, Germany.

Ketten Wälder, established in 1948, set-up cromox, a premium stainless steel brand, approximately 17 years ago. The cromox Chain Hoist (CCH) and cromox Hoist Trolley (CHT) were simultaneously introduced to original equipment manufacturers (OEMs) and the company’s dealer network in 2019.

As was the case at the time of launch, the global cleanroom, pharmaceutical, food and beverage, and hazardous environment industries are primary end-user markets for both products. Ketten Wälder has recently increased stock across three global warehouses — in Germany, the UK, and the U.S. — and has reminded partners of the major benefits of the ranges.

The cromox® Chain Hoist (CCH) is available from 0.63t to 3t capacity.

Roman Auer, chief technical director at Ketten Wälder, said: “We have the broadest range of tested, certified and rated stainless steel lifting products on the planet. Having put the [CCH, CHT] combination to market in 2020, it’s time to re-energise our supply chain and make sure that end users across these key market groups — and others — leverage the benefits of the products. In demanding end-use applications, such as those where the criteria of ATEX and IECEx are applicable, there really are no better material handling solutions.”

The cromox® Chain Hoist (CCH) is available from 0.63t to 3t capacity.

The hoist and trolley are typically used within a single material handling application. The hoist is available in four capacity versions: 0.63t, 1t (both single chain fall), 2t (two fall), and 3t (three fall), known as models CCH-63, CCH-100, CCH-200, and CCH-300 respectively. All are manufactured from Grade 60 stainless steel and are AISI 316L / AISI 318LN duplex (ultrasound) tested. They each offer 3m lifting height, as standard, and weigh between 6.1kg and 11kg.

Other features include high corrosion resistance; a patented sealing system, that creates a sealed brake and gear unit suitable for cleanroom use; a swivel upper hook (locked under load); and a load hook that presents easy rotation, even under full load. There are options for different attachment points and end fittings; and a low headroom version. Customised chain lengths are also available on request.

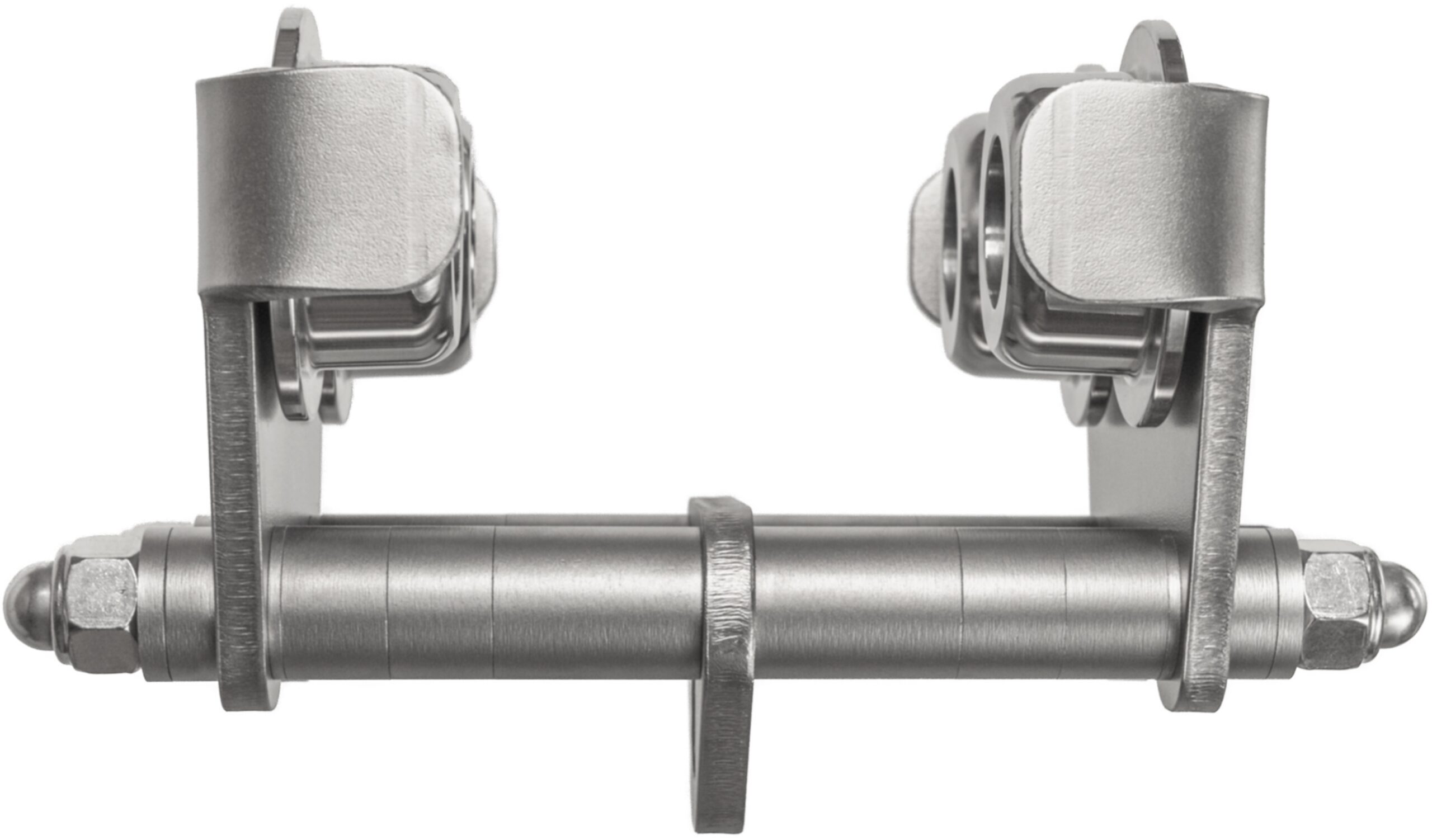

The cromox® Hoist Trolley (CHT), designed for use with the cromox Chain Hoist (CCH), moves the load to different positions along a beam.

The trolley, meanwhile, moves the hoist (load) to different positions along a beam. The trolley is designed for load capacities from 0.63 t to 3t, specifically for use together with the CCH. Like the hoist, the range is stainless steel Grade 60, AISI 316L tested; and manufactured with the highest quality materials to provide a reliable and safe product. Different attachment points and end stops are available, accordingly to customers’ requirements. The trolley is manufactured according to industry beam dimensions.

The cromox® Hoist Trolley (CHT), designed for use with the cromox Chain Hoist (CCH), moves the load to different positions along a beam.

Roman Auer added: “Business is currently healthy; we want to bolster that positivity by reminding key industry sectors of the already popular stainless steel hoist and trolley. Since we are high-tech and very niche, with a broad industry base, we anticipate further interest in the products as 2025 gathers pace. We aim to keep providing our service strength towards our customers; and make sure our stainless steel lifting products are the solution of choice at the point of use — globally.”