Magnetek Variable Frequency Drives

By implementing the latest available features for Magnetek-brand IMPULSE·G+/VG+ Series 5 Variable Frequency Drives, facilities will see increased productivity and reduced potential for injuries and equipment damage during crane or hoist operation.

If you need more information, contact your local Magnetek sales rep.

Plus, users can automatically benefit from these functions to help prevent damage to the crane structure and equipment and, most importantly, create a safe working environment.

Don’t Miss Out on the Latest Compatible Features With IMPULSE·G+/VG+ Series 5 VFDs

Built-In Collision Avoidance Technology

- Built-in feature helps prevent crane-to-crane or crane-to-end-stop collisions, increasing operator safety & reducing maintenance costs

- Easily connect laser sensors to the analog input terminals of the IMPULSE Series 5 VFD, then set slowdown and stop threshold parameters

Radio Drive Serial Interface (RDSI) Systems

- Enable two-way communication between a radio transmitter and VFD via serial interface

- Allow the operator to monitor VFD status information on the radio transmitter’s display unit

DataLogger Series 4 (DLS4)

- Record time-stamped parameters, runs, faults, and alarm histories

- Record time-stamped trending data (similar to oscilloscope)

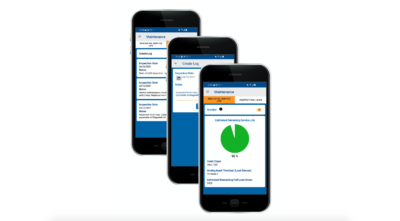

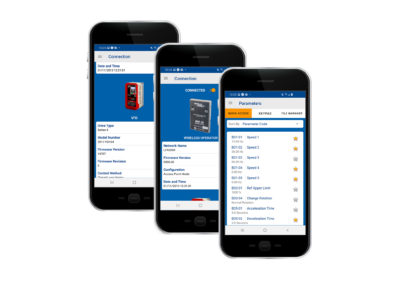

Intelli-Connect Mobile

- Quick and easy programming, monitoring, troubleshooting, and datalogging

- Wireless access to VFDs from the plant floor (iOS and Android compatible)

Coming Soon to IMPULSE·VG+ Series 5 VFDs

- Weight Measurement & Load Summing Features

- Drive Synchronization Feature

Users can benefit from product functions to help prevent damage to the crane structure and equipment and, most importantly, create a safe working environment.

If you need more information, contact your local Magnetek sales rep or our inside sales team at [email protected]