Overhead Crane Firm Now Offers In-House Construction of Box Girder Beams

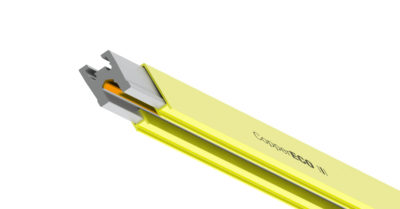

Innovated Industrial Services Inc. has expanded its product line to include construction of box girder beams, ideal for use with long-span, high-capacity double girder overhead bridge cranes and runway beams commonly used in aviation manufacturing, port and terminal material handling, steel distribution/fabrication, concrete products production and other heavy industrial applications. Innovated Industrial also now designs and builds single girder mono-box girders according to customer requirements.

Box girder cranes have a very light weight to span length ratio. In many cases box girders reduce the size of the runway and building structure required to support the lifted load, thus reducing the overall building cost.

“Our recent expansion into a new 9,000 square foot facility enabled us to invest in a box girder fabrication line with proven capabilities for building quality cranes without interrupting our existing 14,000 square foot manufacturing areas. We can now engineer and fabricate double box girders up to 100-foot spans and up to 100t capacity,” said Tom Taphorn, president, Innovated Industrial Services.

Innovated Industrial has invested in a new automated welding process and uses AWS D14.1-certified welders to ensure the highest quality standards. All box girder cranes built by Innovated are fully assembled and functionally tested prior to shipment.

Innovated Industrial Services’ custom engineered spreader beams, below-the-hook lifting devices, fall protection, and overhead crane systems can be found in a number of industries, including boat manufacturing, power plants, steel distribution, pre-cast concrete manufacturing, steel building and construction equipment repair facilities.