Pro-Line Electric Wire Harness Workstations for Aircraft Manufacturer

Tolerances have to be consistently tight when you’re assembling wire harnesses for a jet fighter—1/8 of an inch over 32 feet to be exact. An assembly workstation that can’t accommodate such tolerances would not be acceptable.

That’s one of the problems that a jet aircraft manufacturer faced when it determined it needed to upgrade a facility. Another problem was the ergonomic failings of its old system. It was using pieces of plywood on A-frames for the assembly of extremely elaborate wire harnesses. This not only affected tolerance levels but also led to potential technician stress, strain and fatigue.

Harnessing an ergonomically sound solution

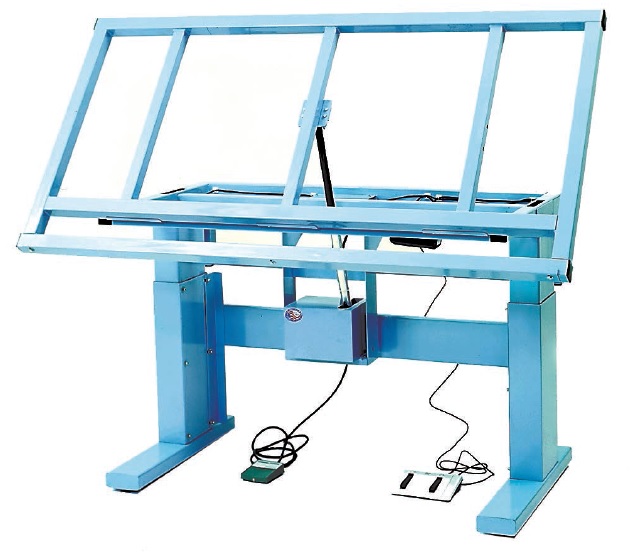

The jet fighter manufacturer consulted Pro-Line of Haverhill, MA, a company recognized as a leader in modular ergonomic workstations, renowned not just for its rugged, technologically advanced workstations, but also for its ability to “think on the fly” and produce, application-specific solutions, Pro-Line delivered Electric Wire Harness Workstations, each retrofitted with a range of accessories. Pro-Line modified its existing technology with new technologies to produce a solution that was ergonomically sound, provided maximum functionality, and met all of the jet manufacturer’s specs.

Thanks to the range of easy vertical movement provided by the Pro-Line system, along with the tilt, all sections of the wire harness are always within easy reach.

Since this initial installation, this jet plane manufacturer has added new accessories to its workstation system, and is currently in the process of expanding its operation with additional Pro-Line workstations.