Chemical Weapons Stockpile Milestone

Bechtel has congratulated the workforce at the Pueblo Chemical Agent-Destruction Pilot Plant on achieving a significant milestone—the initial processing of chemical weapons, bringing the U.S. a step closer to meeting treaty obligations to destroy its remaining chemical weapons stockpile. The milestone marks the first time that the Bechtel-led plant has handled mustard agent.

“Destruction of the U.S. chemical stockpile makes the world safer and helps rid the nation of materials that have been awaiting destruction for decades,” said Barbara Rusinko, president of Bechtel’s Nuclear, Security & Environmental business. “Our colleagues in Colorado have been key to the continued success of this mission.”

The plant was built and is being operated under contract to the Department of Defense’s Program Executive Office for Assembled Chemical Weapons Alternatives.

Full operations will begin following an intermediate phase known as pilot testing. This phase will incrementally introduce more agent-filled projectiles to the plant, ensuring all personnel, facilities, and equipment are working to destroy chemical agent safely, efficiently, and as designed. Some 2,600 tons of mustard agent are stored in munitions located in bunkers on the U.S. Army Pueblo Chemical Depot.

“Introducing mustard agent into the facility brings us that much closer to a world without chemical weapons,” said project manager Rick Holmes. “We could not have reached this important milestone without the dedication of our teammates and their personal commitment to the mission.”

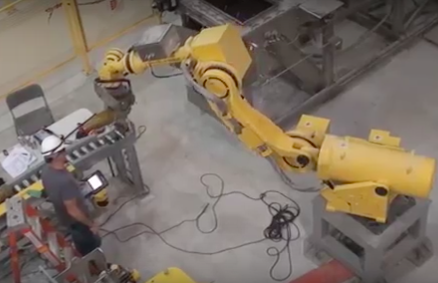

Pilot testing will continue for at least 16 weeks and allow plant operators to study operations data collected during a variety of plant conditions. Robotic equipment will remove the explosive components from each projectile and then drain the liquid agent. The agent will then be chemically neutralized in a caustic solution and the resulting wastewater transferred to the biotreatment stage, which consists of large tanks containing microbes that digest and further break down the solution. The metal from the shells will be heated to 1,000 degrees Fahrenheit for 15 minutes and later shipped off site to be recycled.

A team of Bechtel, AECOM, and Battelle built the plant and conducted three years of systems testing, culminating in today’s milestone.