Electrolift Supplies Custom Twin-Hook Hoist for Gulliver’s Gate

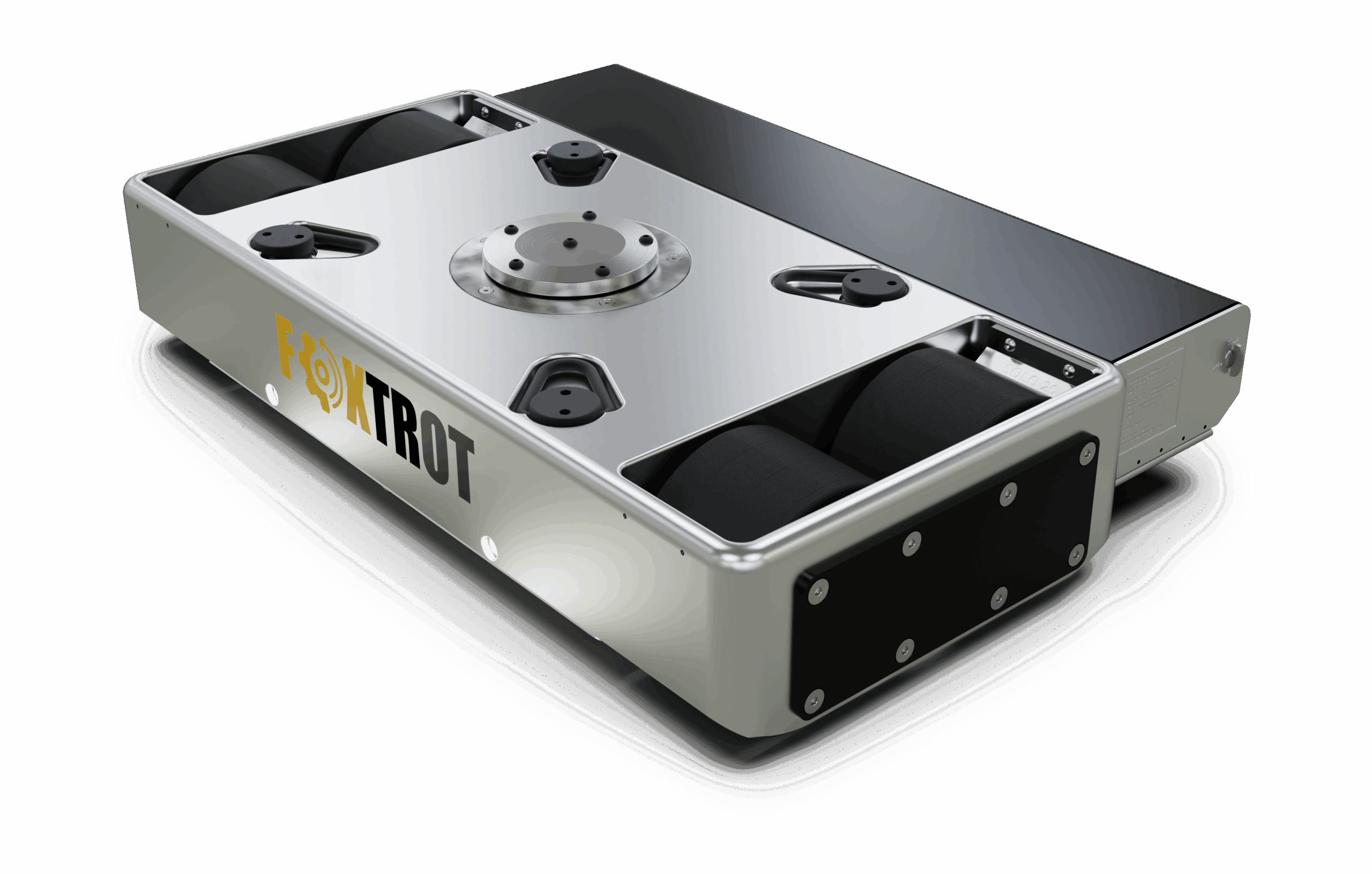

Wire rope hoist manufacturer Electrolift provided a custom twin-hook hoist for lifting valuable models to the second floor of a building at the Gulliver’s Gate miniature world in Times Square, New York.

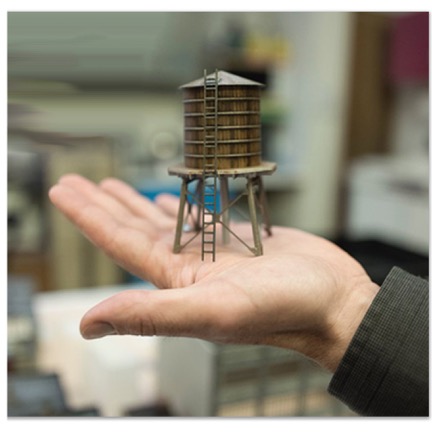

Gulliver’s Gate is a $40 million, technologically advanced, interactive and immersive world of miniatures that covers a 49,000 square foot space at the iconic location.

Matt Cote, chief technology officer at Gulliver’s Gate, contacted New York City-based architect Stanley Wong, founder of SP Wong Architect, to help configure a special lifting solution. Wong contacted Andrew Litecky, head of Shupper-Brickle Equipment Co., of Monmouth County, N.J., and discussed using an Electrolift twin-hook hoist as a custom engineered solution.

‘The hoist has two hooks on it that are driven by a common gearbox so they are synchronized when they move up’—Steve Pilione, co-owner of Electrolift.

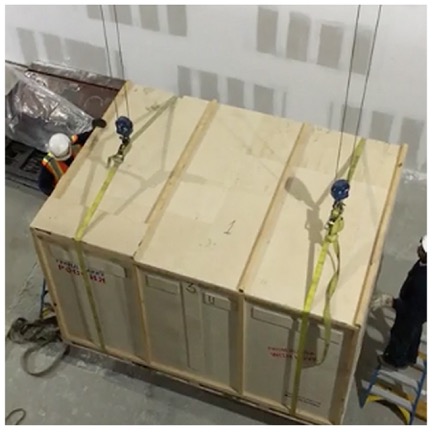

Cote said: “There’s nothing else like it anywhere in the United States. The real physical challenge was having all these models made elsewhere and bringing them into the second floor.”

Steve Pilione, co-owner of Electrolift, said: “The hoist has two hooks on it that are driven by a common gearbox so they are synchronized when they move up. Most other material handlers don’t offer it the solution, but it’s much more stable to pick up a load in two spots instead of one, where you’re trying to find the center of gravity and the cargo could tilt or spin around on the hook.”

Gulliver’s Gate is a $40 million, technologically advanced, interactive and immersive world of miniatures.

Model makers created 1,000 trains, 10,000 cars and 100,000 tiny people, either by hand or 3D printing. Each year, additional ‘citizens’ and vehicles are expected to be added. The Electrolift twin-hook hoist, which was painted a custom colour so it blended in with the blue sky background at the scene, will be used for each addition to the exhibit.

Litecky explained: “Mr. Wong said people from all over the world are having scale models brought in big wooden boxes that have to be raised up safely to an upper floor. Any time you lift a pick you’re talking about a very valuable commodity so you want it to have a smooth ascent.”

Electrolift provided a custom twin-hook hoist for lifting valuable models to the second floor.

Cote said: “I’ve said it to many people that our decision to design and install that overhead hoist was probably the single most important decision we made towards opening on time. None of the other alternatives—manual chain hoists or using the freight elevator—would have worked. Because I was the one responsible for transporting the models in, I personally am very thankful for those decisions and have a great deal of gratitude for them.”

The Electrolift twin-hook hoist will be used for each addition to the exhibit.

Wong added: “Electrolift were local, American-made and a company with a long history—all qualities we wanted.”

Electrolift is the oldest manufacturer of worm drive wire rope hoists. Its wire rope hoists are engineered and manufactured to be rugged and reliable. The standard product line of single-hook, twin-hook, and base-mounted hoists is complemented by custom-engineered systems to meet every type of application. Electrolift has been a family-owned hoist and crane company since 1932.