Irving Equipment Uses Hydra-Slide Low Profile Skidding System For Dryer Change-Out

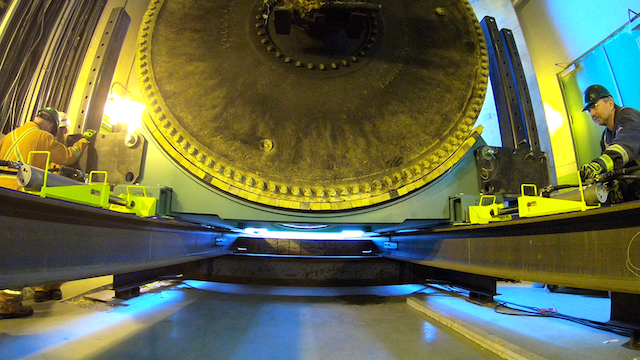

A 350-ton capacity Hydra-Slide low profile hydraulic skidding system was used to change-out a Yankee dryer at a facility in New Brunswick, eastern Canada, recently. The LP350 was utilized by heavy lifting and specialized rigging business, Irving Equipment.

Affiliated company Irving Tissue, a tissue production firm, had a requirement to remove a 55-ton dryer and replace in kind. Both systems were 12 ft. 5 in.-diameter and 13 ft. 4 in.-long cylinders with 4 ft.-long shafts sticking out of either end. Irving was responsible for all movements of the outgoing and incoming units.

The Liebherr was used to hoist the dryer off the second-floor temporary mezzanine that the unit was slid out onto.

Ryan Long, operations manager for southern New Brunswick and Nova Scotia at Irving Equipment, explained that the scope of work presented four standout challenges, namely travel route, second floor location of the dryer, floor strength, and tight confines for blocking up the loads.

In addition to the LP350, Irving employed an Enerpac EVO power pack system and four 50-ton capacity jacks for vertical jacking of the dryer; a pair of 8-ton capacity Broderson carry decks for material handling; and a 250-ton capacity Liebherr LTM1200 all-terrain crane, used to hoist the Yankee off the second-floor temporary mezzanine that the dryer was slid out onto.

Long outlined those challenges in greater detail. Since the dryer was a primary component of an existing in-line paper machine, he said, it was deeply embedded within the plant and required the project team to make three directional changes and three elevation changes to avoid existing infrastructure.

The innovative in-house solution of a ratcheting jack-post design eliminated the need for blocking.

Long added: “As the dryer was on the second floor of the plant, in order to get it to ground level a temporary mezzanine was designed and installed outside of the plant at the same elevation as the sliding system, and the back wall of the plant was removed. This allowed us to slide the dryer completely outside of the building and onto the mezzanine before lifting it off with our Liebherr LTM1200.”

It was determined that the concrete floor of the building could not support the loads that would be imposed by the dryer as it travelled along its path. In order to mitigate this, a steel grillage system was engineered and installed to bridge the floor between supporting columns under the floor for the entire route. Since the dryer removal was part of a larger overall shutdown, the grillage system had to be installed in a sequence that didn’t impede that scope of work.

Standout features of the LP350 system include a low-maintenance graphite-steel slide surface, and a ratchet track design, allowing the push cylinders to automatically reset at the end of each stroke.

Innovative solution

The underside of the installed dryer was approximately 5 ft. off of the floor, which made for a considerable amount of blocking to be done when lowering it down to the floor. “Combined with the awkward 5 ft. of space, we knew it would be time-consuming and hard on the rigging crew to do all of that work while hunched over,” Long said. “It screamed soft tissue injury! To overcome this, one of our team members [Mike Neill] hatched the idea for a very clever ratcheting jack-post design that eliminated the need for blocking.”

The LP350 eliminated the need to remove a roof section and lift out the dryer with a 500-ton capacity class crawler crane, which would have added significant mobilization and crane pad costs. The Hydra-Slide system was compact and easy to use within the tight confines of the plant. The method also facilitated the three required directional changes in 31 ft., 38 ft., and 135 ft. increments, with the aforementioned elevation changes along the way.

Both dryers were 12 ft. 5 in.-diameter and 13 ft. 4 in.-long cylinders with 4 ft.-long shafts sticking out of either end.

The slides took place across two 12-hour shifts. Outside, the LTM1200, part of Irving’s fleet of 100-plus cranes, lifted the dryers with a Modulift spreader beam beneath the hook and slings basketed around the dryer shafts. The paper machine was shut down whilst the dryer was being replaced.

Importance of training

Long stressed the importance of training to successful implementation of the LP350, which boasts a total height of less than 1.5 in. (38mm), reduces jacking time, and is ideal for situations where overhead space or clearance is limited, such as inside buildings or within live power stations. Robert Young, director of operations at Hydra-Slide, conducted two visits—once for crew training and then as site support during the moves.

Long said: “Training is critical to our success; without it we would be doing a disservice to our employees and clients. Part of the reason we invested in the [LP350] system was the confidence we got from meeting with the Hydra-Slide team. The fact that they are personally invested in the quality of their products and clearly have a passion for what they do is very important. We knew that they would provide the level of customer support that would ensure our success.”

The LP350 eliminated the need to remove a roof section and lift out the dryer with a 500-ton capacity class crawler crane.