Light Directed Picking System for Order Fulfillment

Dematic, a supplier of integrated automated technology, software and services to optimize the supply chain, has introduced the next generation light directed picking system for order fulfillment. The new version includes enhancements that support increased picking efficiencies, higher pick rates, and more operational flexibility.

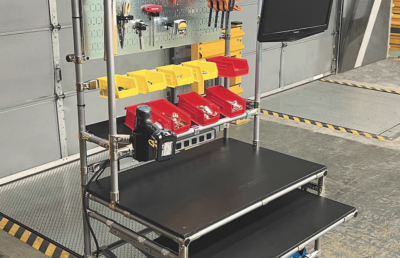

The Dematic light directed order fulfillment system is a standardized, pre-engineered solution that can be configured as a pick-to-light or a put-to-light method of piece and case picking.

The Dematic light directed order fulfillment system is managed and directed by Dematic iQ Warehouse Execution System (WES). The WES software manages and directs the picking staff while synchronizing workflows to accommodate the priorities and demands of order fulfillment. Dematic iQ optimizes the light directed picking process to reduce order processing time, accommodate peaks in order volume, enable increased order accuracy and align tasks to meet demand.

New features include dynamic zone balancing, active order hand-off, and operator enter/exit. Dynamic zone balancing allows operators to be more efficient since the software expands or contracts the picks zone boundaries to accommodate work load. Active order hand-off provides operators with the ability to turn over picking tasks to another operator. Operator enter/exit permits operators to be inserted or removed at any point in the system to accommodate peaks in activity or low volume activity.

The Dematic light directed order fulfillment system is a standardized, pre-engineered solution that can be configured as a pick-to-light or a put-to-light method of piece and case picking.

According to Mike Khodl, V.P. Solution Management with Dematic, “The next generation of the Dematic light directed order fulfillment supports higher overall picking rates since operators can go exactly to where the work is. Operational flexibility is built into the system to allow efficient picking of a wide variety of order profiles. The software dynamically balances the work to be performed so no one operator is overwhelmed or waiting for work.”