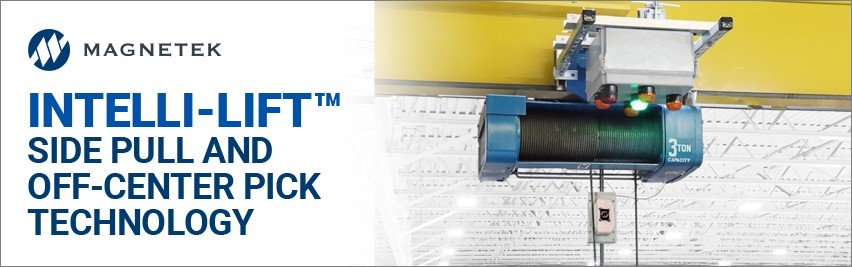

Magnetek Detection, Prevention Systems

When lifting a load, it is important it remains centered under the hoist to prevent load swing or harm to the operator and surrounding equipment. Magnetek’s Intelli-Lift can help.

The Intelli-Lift System detects a load misalignment or snag condition and alerts operators before a dangerous situation occurs. From there, the misalignment or snag can be corrected manually or automatically by the Intelli-Lift System.

The Intelli-Lift System detects a load misalignment or snag condition.

Intelli-Lift is available in two system options, depending on application needs:

Detection system

The status control enclosure provides visual notification of a misalignment or snag event via directional lights with an optional warning horn. An operator may manually correct the load misalignment.

Prevention and correction system

Prevents lifting when load is misaligned and will stop the bridge and/or trolley motions when a side pull or snag is detected. This system then allows the operator to manually or automatically correct the load.