Creform Kitting Cart Covers Up

Creform Corporation, a manufacturer of products for material handling and commercial use, has designed and built a kitting cart fitted with a sewn cover to keep cart and materials clean. The user, in the logistics business, asked for help in developing a kitting cart that could be loaded at their facility and then transferred a short distance by truck to their customer’s plant.

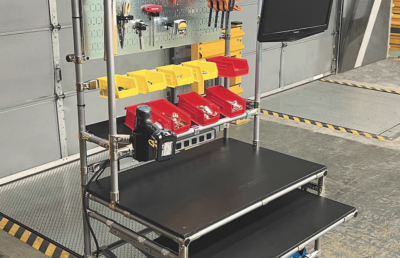

Creform designed a special four level shelf cart. Each shelf features a sold surface and a pipe lip around the perimeter to ensure that the product stays on the shelf during transit. The custom cover features magnets to hold it in place while one side can be rolled up to access the cart for loading/unloading.

The cart’s dimensions are 26″ Deep x 38″ Wide x 70″ Tall and is designed to hold up to 375 lb. It is suitable for either manufacturing or warehouse use. It features four 6 in. diameter casters for easy, stable and safe movement. The large diameter casters are ideal to facilitate easy loading/unloading. Near the base of the cart, each corner features a

3 ¼ in. diameter rubber cushion ring for protection. The ring also holds the cart frame from hitting the truck wall during transport.

A separate floor lock is integrated into the base to hold the cart in place. Wheels lend themselves to easily moving the structure for transport, housekeeping and/or repositioning. Products that are handled include a number of long items so the cart features six hooks to hang those items for safe handling and easy retrieval.

Creform kitting cart also shown with protective cover down at right.

As with all Creform carts, higher capacity and custom cart sizes and configurations are possible with the Creform system of 28 mm, 32 mm and 42 mm plastic coated steel pipes and metal joints. They can be configured for ESD (anti-static) applications.

A wide variety of pipe color options are available and upgrade hitches are available for AGV or tugger delivery. Accessories include hooks, label holders for shelf levels or even shelf positions, writing surface with clip boards to name a few. Creform carts are available as a kit, assembled structure or in component form for a complete DIY solution

The Creform system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and Lean Manufacturing programs. The company partners with customers in developing and implementing these programs.