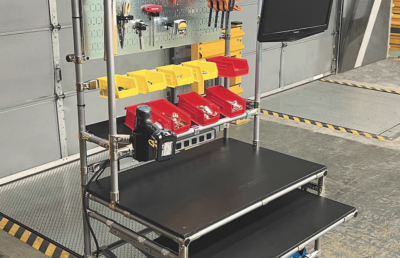

Angled Shelf Rack with Bins

Creform Corporation, a manufacturer of unique products for material handling and commercial use has designed and built and angled shelf rack with bins designed to hold light weight plastic brackets to support a manufacturer’s assembly operation.

In this application, Creform assembled the racks prior to shipment for the customer’s quick implementation. It is one of six used by the automotive parts supplier.

The rack, featuring six heavy-duty feet threaded for floor leveling capability, can be used as an individual rack, for picking specific SKUs or by connecting several together, with brackets, becomes a large-scale picking supermarket rack. As an individual rack, it can be easily disconnected and pulled out for adjustment, maintenance or relocation. Due to its compact size, a small supermarket storage area can be nestled into the production area close to point of use as well as in a dedicated warehouse space.

The flow rack pictured is 45″ W x 32″ D x 67″ T and is rated for up to 300 lb. load capacity. It features five levels for product presentation with two lanes across each level. Each of the rack’s levels can be repositioned or whole shelf rack customized with simple tools.

Each flow lane features a fabricated corrugated plastic trough that is open at the back for easy loading and includes a center relief cut-out of the front to access the parts. This vertical rack provides high density storage that is possible for efficient picking.

The flexibility provides for high-volume usage parts between waist and chest high, low- volume usage on the lower levels. The vertical presentation allows the angled shelf levels to help keep parts at the front of the bin within easy reach.

Creform rack with angled shelf and bins.

As with all Creform fracks, higher capacity, sizes and configurations are possible. A wide variety of pipe colors are available for ESD applications, and accessories can include information sheet holders, label holders, tool storage, hooks to hang tools and other supplies. Creform racks are suitable for warehouse or manufacturing plant use. They are available as a kit or an assembled structure or in the component form for a complete DIY solution.

The Creform system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and lean manufacturing programs. The company partners with customers in developing and implementing these programs.