JLT Mobile Computers Test Center

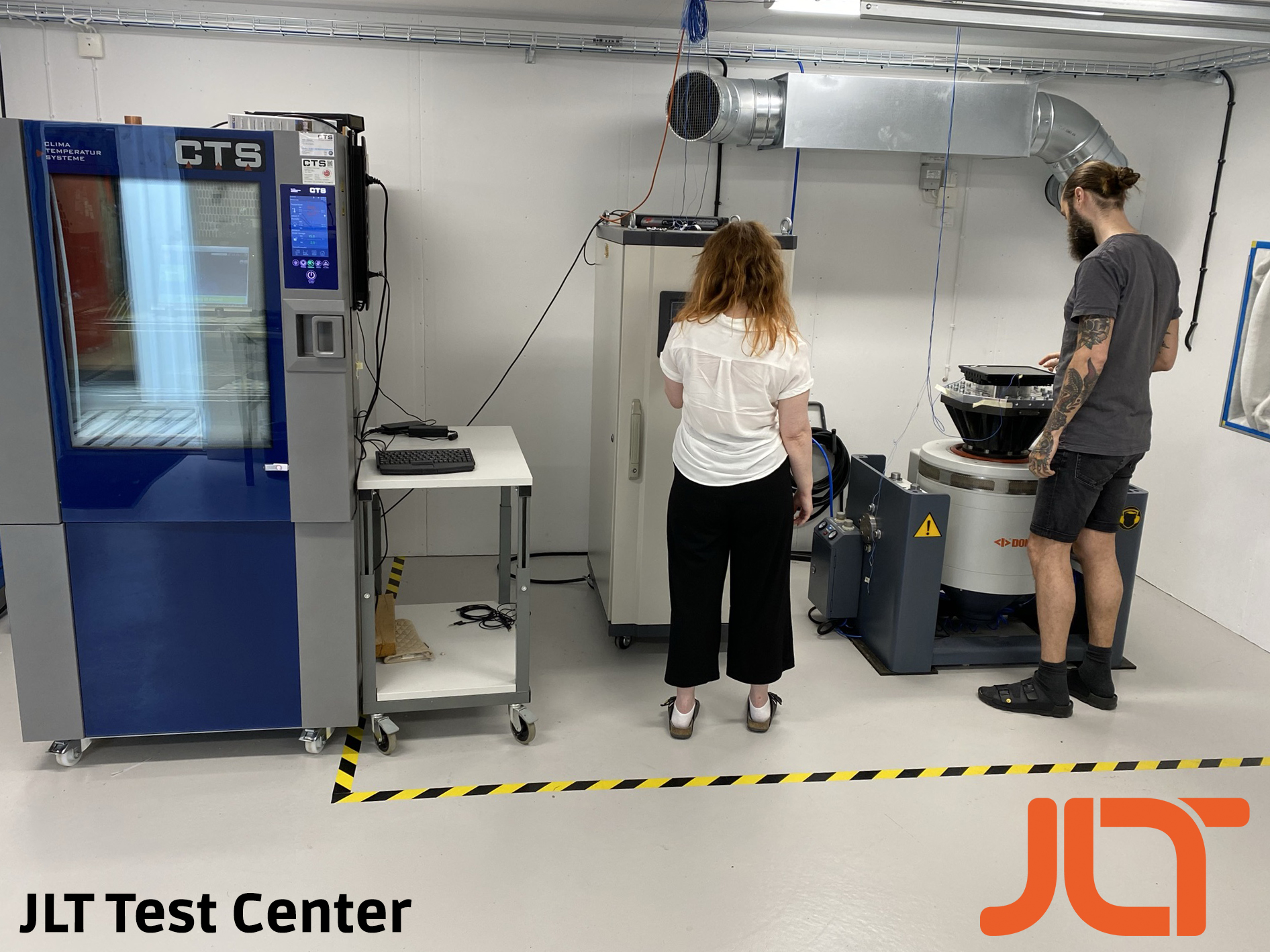

JLT Mobile Computers, a developer of computers for demanding environments, has launched the JLT Test Center, established to gain full control over the already high quality and extreme durability of existing JLT products and to enable more efficient development and testing of new offerings.

- The new JLT Test Center is part of JLT’s expansion and growth strategy and the company’s commitment to excellence in its markets.

Conforming to industry pertaining ruggedness and operational standards is second nature to JLT and comprehensive environmental testing is crucial to the performance, durability and reliability of rugged computing equipment as it routinely undergoes stress far in excess of what standard consumer technology can handle. JLT has always designed, engineered and manufactured equipment that holds up in the field, increases customer productivity and improves worker satisfaction. With the ability to test products inhouse under all conceivable customer operating conditions and at all stages of development, this process now becomes both more time and cost-efficient.

“We want for our customers to rest assured that we’ve always tested every aspect of the units that their business relies on in detail and to the extreme. With our new test center, we can subject our products to the harshest environmental punishment they may encounter in the field, and beyond, without the need to involve external testing labs and with minimal time delays. If something breaks, we go back to the drawing table to make it better and stronger, right here in our own facilities,” said Per Holmberg, CEO of JLT Mobile Computers. “Our new test center is state-of-the-art. We can test for shock and vibration, temperature extremes, humidity, impact resistance and we also do radio frequency testing. This enables us to develop the ultimate balance between the highest quality, reliable products, internal efficiency, and production costs. It is also a great facilitator for future innovation.”

While JLT has been testing computing equipment at its facilities before, the new and expanded JLT Test Center ensures even greater inhouse capabilities. For example, the new vibrator/shaker can test PCs and displays for shock and vibration resistance, both perennial issues for units deployed in moving vehicles and multi-shift operations. Testing for weak points and making the necessary adjustments maximizes uptime and can add years to a product’s life.

JLT’s new programmable climate chamber can run automated temperature sequences for hours and days, closely matching real-world temperature cycles and extremes. And the new chamber’s humidity control adds a new dimension to inhouse testing, measuring the impact of extreme humidity and changes in humidity on performance and reliability.

The test center’s radio lab allows JLT to prequalify components and designs for electromagnetic compatibility (EMC) and electromagnetic interference (EMI) before sending devices for official testing and certification, reducing uncertainty and expediting time to market. The radio lab also allows configuring for optimal radio performance and wireless connectivity under varying conditions and usage scenarios.

The new vibrator/shaker can test PCs and displays for shock and vibration resistance, both perennial issues for units deployed in moving vehicles and multi-shift operations.

All of this allows the JLT Test Center in Växjö to do the kind of development testing that enables the company to detect and fix issues early in the development process, test new design ideas, test specific custom designs, and even replicate a customer’s specific working environment.

JLT Mobile Computers has long encouraged its customers to “try before you buy” – making sure that units not only meet needs, but hold up in customers’ specific work environments, no matter how harsh they are. With the new JLT Test Center, customers can be more confident than ever that JLT products will meet and exceed expectations.

- To learn more about JLT Mobile Computers, and the company’s products, services and solutions, visit www.jltmobile.com.