Custom Mobile Workstation

Creform Corporation, a manufacturer of unique products for the design and building of material handling structures and automated guided vehicles, has developed a mobile workstation for a truck parts supplier.

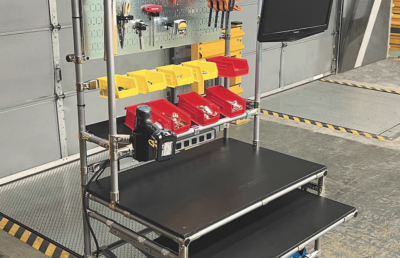

The workstation, built for standing work is constructed using Creform’s 28 mm pipe and joint system and features plastic work surface across the front, as well as a shelf below the work surface across the front that is used for parts, supplies and tools/fixtures. Above the work surface are two flow levels with angled presentation for the parts holding totes.

Flow lanes provide first-in, first-out parts handling while the presentation created by the secondary angle enhances visibility and physical access to the parts. The angled presentation also keeps the loose parts in the totes positioned to the front of the box for easy picking. At the top of the workstation are two flow lanes to return the empty totes to the rear of the workstation for an associate to pick up when bringing full totes to restock the station.

The workstation has overall dimensions of 65″ W x 83″ H x 47″ D with a 600 lb. load capacity. It is built with “Marine Blue” colored plastic-coated steel pipe and metal joints and features industrial-duty stem casters which makes workstations easy to reposition for a change of the shop floor layout or for housekeeping.

The modular design allows the user to add only the accessories needed and he can configure the station that works best for him today and then change it tomorrow as needs change. He can take advantage of the Creform system’s flexibility by changing the station’s configuration and features to best match the needs of their production process as well as the stature of the manufacturing associates.

Workstations can be custom configurable with the Creform system of pipe and joints and can be built as a stand-up or a sit-down station. They can be available as an assembled structure or kit with pre-cut pipes for quick on-site assembly. Further, the workstation can be mobile or stationary. For heavy duty applications they can be built using Creform’s unique 42mm pipe and are available with options such as drawers and shelve for storage, various pipe colors, feet instead of casters, tools and cup holders.

The workstation has overall dimensions of 65″ W x 83″ H x 47″ D with a 600 lb. load capacity.

Useful accessories for such a station include overhead light, computer screen, shelves, additional flow lanes, drawers, information sheet holders, label holders, tool storage, and hooks to hang tools and supplies. All Creform workstations can be configured for ESD applications where sensitive electronics need to be protected.

The Creform system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and Lean Manufacturing programs. The company partners with customers in developing and implementing these programs.