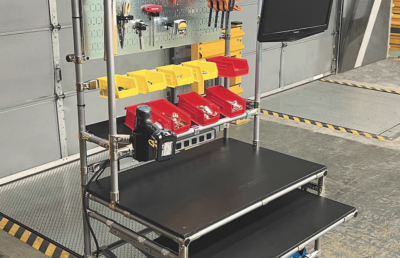

Automotive Mobile Flow Rack

Creform Corporation has designed a wide mobile flow rack for lineside use for a large automotive assembly plant.

The assembly plant uses this rack to help flow production parts to the line and for its flexibility and reusability.

The rack is built utilizing Creform’s 28mm pipe and joints. The silver metallic color of the pipe and the silver nickel metal joints selected by the user, supports the plant’s aesthetics. It features Creform’s skate wheel conveyor, selected for its excellent flow characteristics and value. The low-friction skate wheel conveyors allow for shallow flow lane angles that are suitable for both plastic returnable totes as well as cardboard boxes. The gravity flow rack assists in first-in, first out (FIFO) inventory management.

Each of the top two flow lane levels of the flow rack features ten skate wheel conveyors and provides the flexibility to handle a wide variety of box sizes and types. In this instance there are no lane dividers for complete loading flexibility and the very top supply level is set back 6 inches to improve access to parts in the boxes presented below. There is also an empty container return level on the bottom. The rack includes some extra height to allow for plenty of room to adjust the levels

Each of the flow rack’s levels can be repositioned or the whole flow rack can be customized with simple tools.

The flow rack pictured is 50″ W x 72″ D x 72″ T and has a load capacity rating of 600 lb. It features six 4 in. casters for easy movement–four swivel wheels with two featuring brakes. Two fixed casters in the middle help provide better steering control when moving the flow rack from one location to another.

Besides lineside use, the Creform flow rack can be part of a supermarket storage area. It is ideal for picking individual SKUs that make up a manufacturing kit, typically appropriate for assembly applications. The flow rack is also useful for general storage of pull-to-ship parts and point of use presentation rack within an assembly work cell.

Creform wide mobile flow rack for lineside production use.

Per the customer’s request, this unit was built with silver metallic pipe color, but as with all Creform flow racks, a wide variety of pipe colors are available, and accessories can include information sheet holders, label holders, tool storage, hooks to hang tools and other supplies. As well as built with feet, rather than wheels. Creform structures can be built with ESD for anti-static applications and are available as a kit, an assembled structure or in the component form for a complete DIY solution. Creform’s most noted benefit is its complete dimensional and capacity flexibility of its structures.

The Creform system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and lean manufacturing programs. The company partners with customers in developing and implementing these programs.