CP&A Wind Analysis at Port

Casper, Phillips & Associates Inc. (CP&A) has played a central role in creating a Site Wind Analysis and Monitor (SWAM) program, based on anemometers and weather forecasting technology, for Global Container Terminals (GCT). The revolutionary system has been nominated for an industry award.

GCT’s Deltaport is Canada’s flagship container terminal. The 210-acre state-of-the-art site is in the outer harbor at Roberts Bank (Delta, B.C.), supported by a 3,609-foot contiguous berth, and a dock rail with 27,350 feet of tracks. Over 18,000 containers are typically stacked at any given time.

GCT identified the need to refine the port’s wind policy; the site is exposed to largely unobstructed Pacific Ocean winds via the Strait of Juan de Fuca. Port management lacked clear references, leaving unplanned shutdowns as the only course of action. These delays had a significant impact on operations, customer service, and safety.

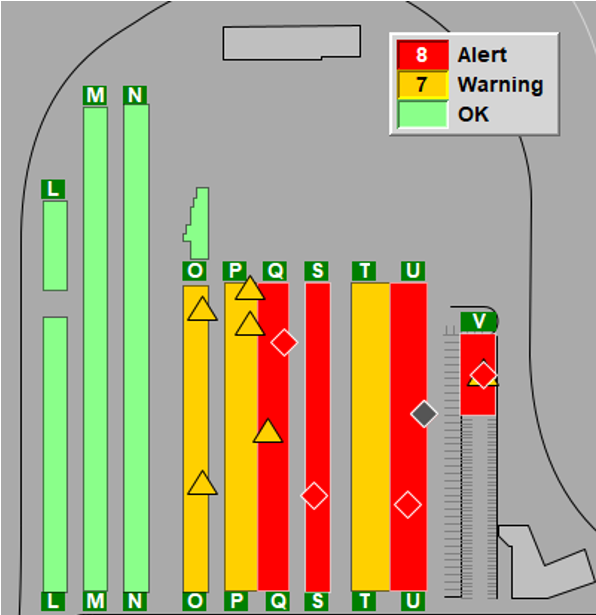

Illustration of container risk warnings and alerts.

Empty vessels

CP&A — the company offers a wide variety of services, including procurement, specification, design, manufacturing review, modification, and accident investigation — was called in to review the policy, with a primary concern being stacks including empty containers. A change in the yard planning model no longer allows the isolation of empty containers, which can fall into roadways and other areas, causing damage and hazards to personnel.

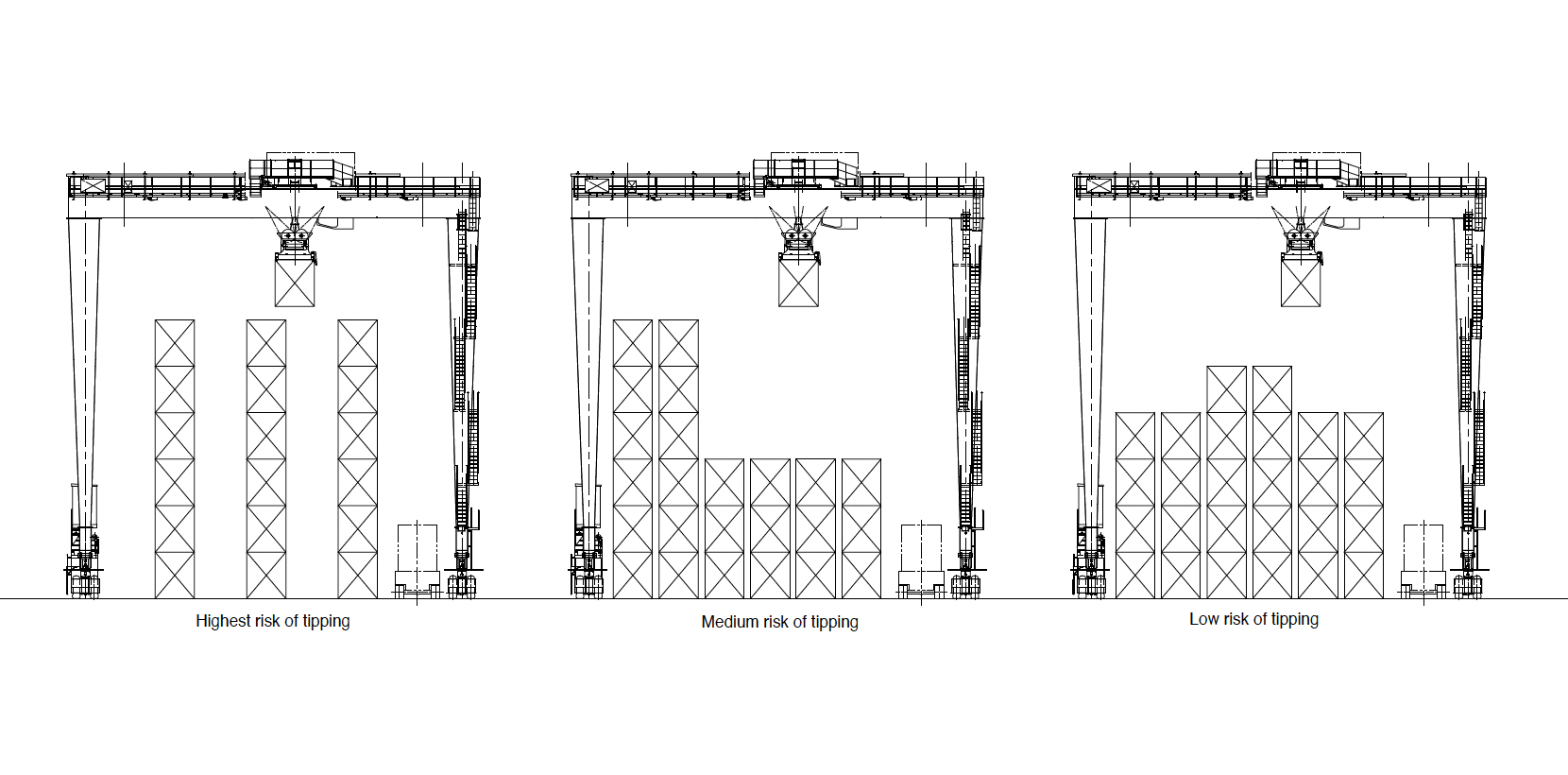

Richard Phillips, mechanical engineer at CP&A, said: “The heavier the containers, the higher the wind force required to move them. The lighter the containers, the easier it is to push the stack over.

“We discovered that the safe shutdown wind speed varied greatly depending on how the containers were stacked, which led us to propose creating either a stacking policy or using the TOS [terminal operating system] to calculate a real-time safe wind speed based on how the containers were stacked and their weights. GCT chose the latter.”

Exposed to the elements: Deltaport berths one, two, and three — as seen from the top of crane 12.

CP&A delivered back-end programming, incorporating the engineering analysis and math. It was apparent that the port’s rubber-tired gantry (RTG) cranes had their own shutdown speeds set by the manufacturers, irrespective of the yard where they operated. Furthermore, the fleet of cranes was built by multiple manufacturers with anemometers located at various heights. A separate array of anemometers was therefore proposed to measure wind speed in close proximity to containers.

GCT led on the front end programming, including the human interface and display graphics, and hired contractors to build and install the anemometer array designed by CP&A. The project went through a trial period where the original wind policy remained to ensure the new system accurately assessed the risk of containers sliding and / or tipping. Notably, this trial period was also used to observe the accuracy of the weather forecasting research team at the University of British Columbia.

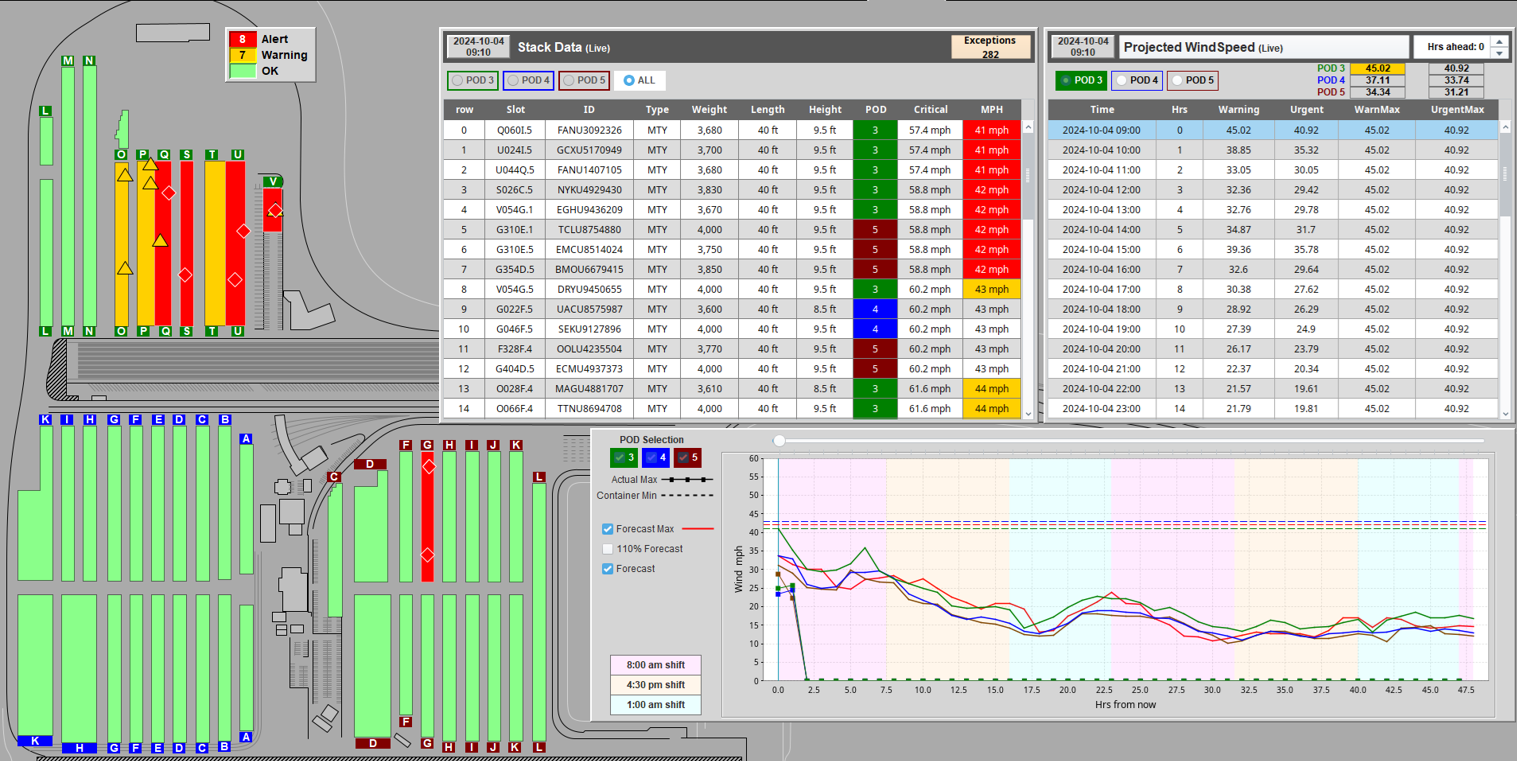

Stack monitoring interface.

Phillips added: “Typically, anemometers are installed at a height of 33 feet. However, the standard height would not be ideal for this application since the tallest RTGs are 89 feet tall. We designed a bolt-on array that connected to the existing light poles at a height of 98 feet. Each array has three anemometers, 120 degrees apart. Based on the direction of the wind, only two anemometers are considered valid since one of them will likely be shielded by the light pole. We chose three because if one anemometer goes down, there will be at least one good anemometer per array.”

Automated system recognized

The cranes’ load cells were also utilized; each time a crane picks up a container, it communicates both the weight and box number to the TOS. The box is tracked as it is taken off the ship and stacked in the yard. The TOS system sends data, including the weights of the boxes and the stack configuration, to the SWAM program, which automatically calculates the safe wind speed and compares it to the measured wind speed from the array. There are future plans for integrating artificial intelligence (AI) and machine learning into the system, Phillips said.RTG – Stack picks labels

Container stability is very sensitive to stack configuration.

The SWAM program is the only known system that offers integrated weather forecasting that predicts the likelihood of shutdowns in advance. This allows GCT to better plan operations and notify vessels, which presents safety and productivity advantages.

Roy Kristensen, director of engineering at GCT, said: “The implementation of the upgraded wind system has significantly enhanced both operational safety and customer service. By integrating advanced forecasting technology, container dynamics studies, and real-time wind monitoring, GCT has shifted from reactive measures to a proactive, data-driven approach in managing wind-related risks.”

- The program was nominated for an Innovation in Safety Award, sponsored by TT Club, a provider of insurance and risk management services for the transport and logistics industry.