Cranes Operate on Temporary Shoring Columns

Forty 10-ton wireless compression load cells from Straightpoint monitor forces on temporary shoring columns used to support two tower cranes during the Century City Mall project on Santa Monica Blvd., Los Angeles, California.

Two cranes from rental company Mr. Crane, supplied by Morrow Equipment Co., are supported by the existing columns and shoring posts, as load cells calculate total mass and center of gravity of the cranes and subsequent lifted loads.

Both cranes are located on an existing, two-floor, underground parking garage. A Liebherr 630 EC-H 20 Litronic is stationary, while a Liebherr 542 HC-L18 Litronic operates on rails and traverses the length of the project in stages. The cranes used to erect them on the garage were a Liebherr LR1300 crawler crane and a Liebherr LTM1400-7.1 hydraulic truck crane. There is a third tower crane—another 630—on a standard foundation on the ‘Macy’s side’ of the project.

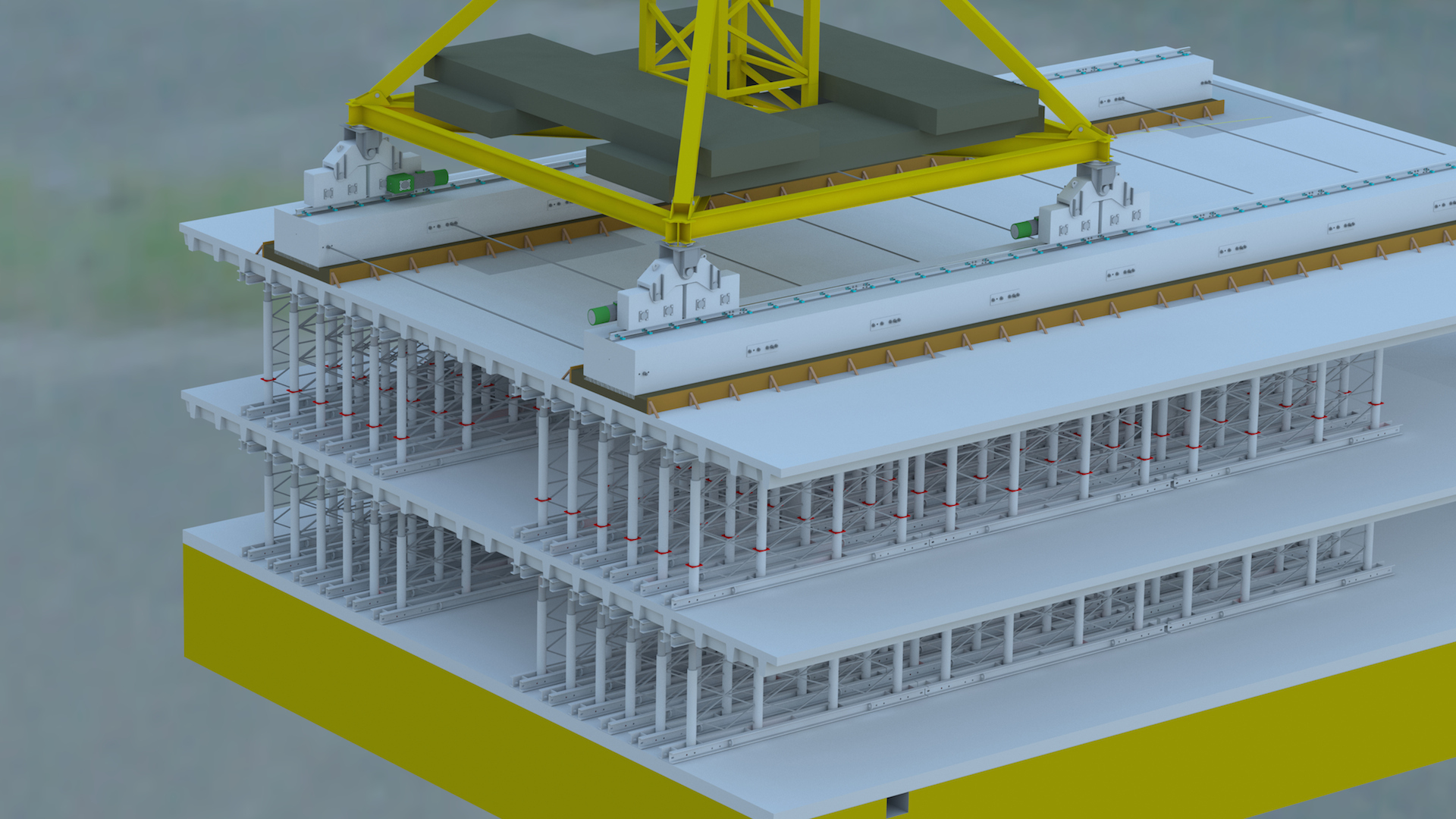

Each crane is supported from the deck down to the final slab of the structure using jackscrew shoring posts on both floors of the car park, positioned at each of the four corners of the stationary crane, and along the pathway for the traveling crane.

Mark Sovocool, engineering manager, Mr. Crane, said: “The track system is a typical Liebherr bogie and track system, with electrically driven bogies. What is under the track is anything but typical. We came up with a block system, with blocks designed by Coreslab Structures (LA) Inc., to support the track and crane that can be easily removed once the project is complete.”

The Liebherr 630 stationary crane on the garage deck is in the foreground, while the LR1300 is prepared for dismantle, and the ‘Macy’s’ tower crane is behind.

Traversing the roof

The tracks sit on two rows of 20,000-lb. concrete blocks extending approximately 100 yards across the top of the parking garage. The temporary shoring columns and wireless load indicating compression load cells are moved across the parking garage below as the crane transverses the roof top overhead.

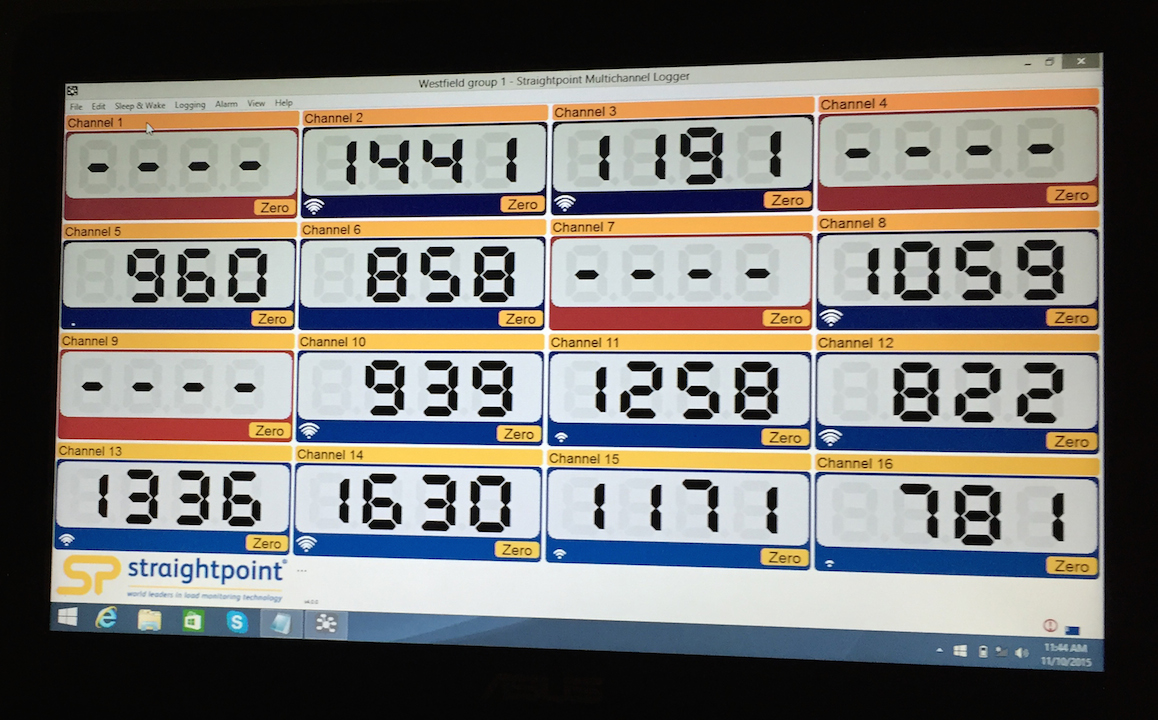

John Molidor, general manager, Straightpoint Inc., said: “A sampling of the shoring column loads is provided by 40 wireless 10 ton compression load cells. The wireless load data is transmitted to a Windows PC (or tablet) running our SW-MWLC software. The software’s web server function transmits the real time load data via a local area network to the tower crane operators high above, allowing them to view the live loads on mobile technology such as an iPhone or Android device. Our SMS alert system is employed to monitor the loads associated with the cranes. Maximum load thresholds are established and if reached key engineers and project administrators will be automatically notified via email and text of the alarming conditions.”

Sovocool added: “It is important to monitor loads so we can check there is a good distribution of force onto all of the shores in the immediate vicinity of the crane. The load cells allow our personnel to walk around the shoring posts and get wirelessly live readings of the force under a sampling of the shore posts, giving us some idea as to what the posts are actually seeing as the crane swings, and in some cases travels. The goal was to ensure that no single post was overloaded.”

An early rendering shows a cross-section beneath the traveling crane. This is an initial concept and not accurate to final installation but it shows where the load cells were placed at the top of a sampling of posts on each level.

The whole project is a remodel and expansion of the mall. It involved clearing existing structures on the top floor (shops), reinforcing structural components and erecting steel for the new sections of the mall. Typical loads are below 20,000 lbs., with some critical lifts up to 42,000 lbs.

The mobile cranes have been removed from the project, but all three tower cranes remain. The load cells on the two garage supported tower cranes are still in place.