Custom Material Handling Cranes Center Stage as Ace Returns to ProMat

Overhead crane and hoist manufacturer Ace World Companies will showcase custom material handling solutions on Booth S5056 at ProMat, which takes place 3-6 April 2017 at McCormick Place, Chicago.

It represents a much anticipated return to the ProMat show floor, nearly two decades after Ace last exhibited at the manufacturing, distribution and supply chain event. The manufacturer is a frequent visitor to both of trade show Material Handling Industry’s (MHI) major events—MODEX takes place on alternate years in Atlanta, Georgia—but more commonly exhibits at end user industry specific shows.

Camron Ghanemi, vice president, explained that more favorable market conditions and the opportunity to offer a differentiated material handling solution were the combining factors behind the decision to take a booth this time around.

He said: “We pay close attention to top-ranked economist, Jason Schenker, who recently shared his latest short- and long-term forecasts with the MHI annual meeting in Tucson. Supported by our own intelligence, we believe the outlook is favorable enough to support a custom lifting equipment exhibit at the 2017 show.”

Ghanemi added: “We’re one of very few specialty, custom manufacturers that will be at the event and we hope to seize the opportunity to engage a captive audience. Who else at ProMat could offer visitors a 100 ton capacity custom material handling crane, for example? I walked the aisles of the 2015 show and am confident that our marketing savvy and engineering expertise will combine to create one of the most talked-about booths at McCormick Place.”

Ghanemi will be joined by Stacy Thomas, marketing manager; and Tad Dunville, director of corporate development on the booth. Ace hopes to welcome decision makers, influencers and end users of overhead lifting equipment, but Ghanemi said branding is also a key component of the ProMat strategy.

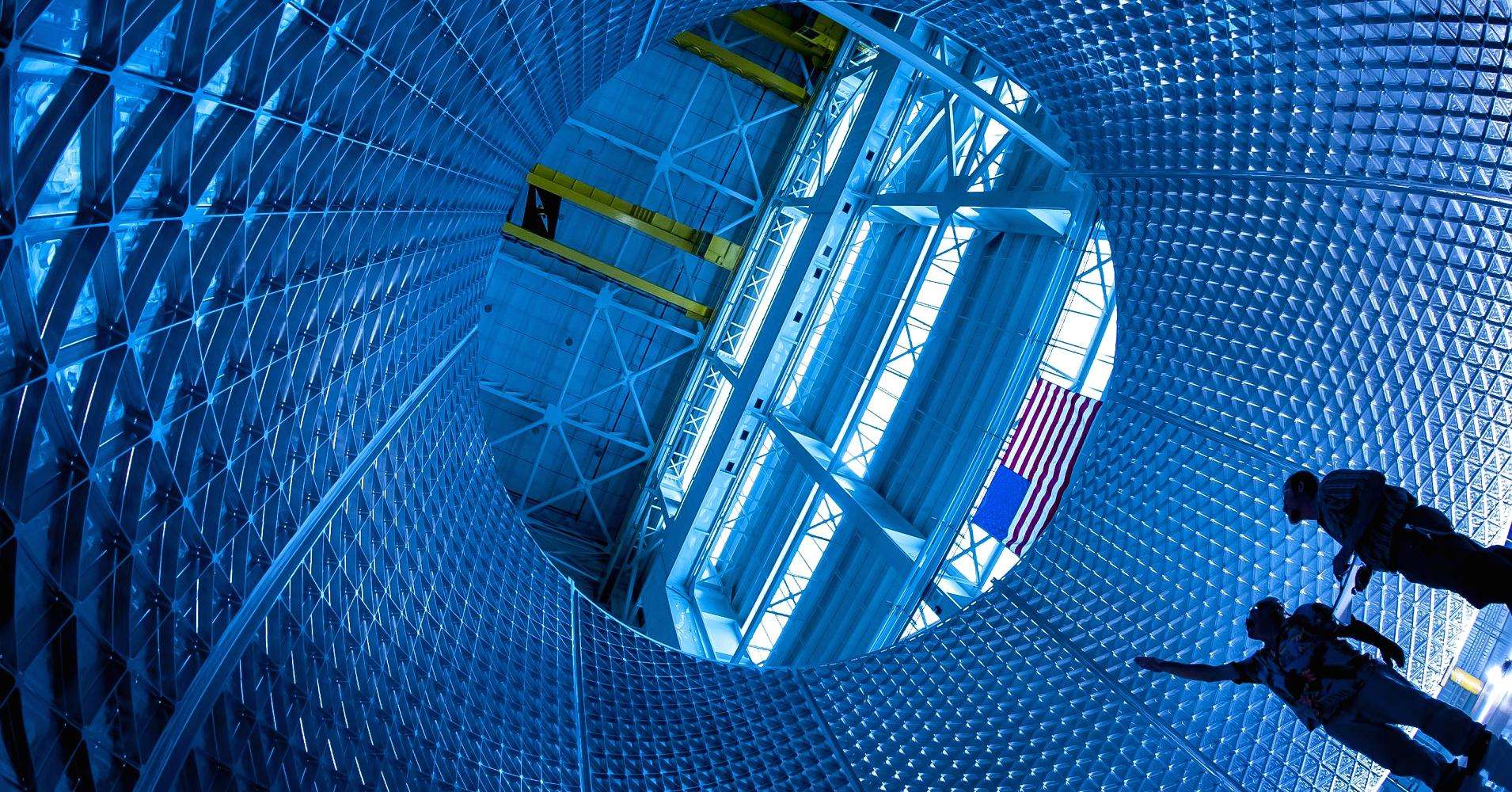

Ace World Companies has engineered many custom overhead cranes, including this one installed at NASA.

Dunville added: “It’s important to offer visitors a balance of expertise, but we set ourselves apart in having engineers on hand to help answer questions or conceptualize a project. It is necessary to have technically astute people at a booth with a product like ours because we don’t sell a commodity product and an entry-level sales person wouldn’t be the best option for interacting with buyers. Different to an end user industry specific event, we need to present an overview of our capabilities, whilst raising the profile of the brand and networking with existing partners, vendors and other contacts.”

Dunville anticipates interest in the company’s load float software, which has been developed for high duty cycle cranes. He explained: “Load float is a generic term that describes a situation where the controls feed enough power to the hoist motor to hold the load stationary as if the brakes were on, but actually the brakes are not on and the load is not resting. This is a proprietary piece of software we use on our drives as a value add in case a brake fails.”

Thomas, meanwhile, has urged existing and prospective customers to visit Booth S5056 where product information and sales literature will also be available.