Dematic Robotic Order Fulfillment System for Aussie Supermarket

Dematic, a supplier of integrated automated technology, software and services to optimize the supply chain, will implement a robotic order fulfillment system for Drakes Supermarkets, an independent grocery retailer based in Australia.

The new robotic system will be used to piece pick inventory items for retail store replenishment using a “goods-to-robot” configuration. The new order fulfillment system will support replenishment of approximately 50 retail stores and is scheduled to start up during the 2nd quarter of 2019 in a new distribution center building.

The Dematic robotic order fulfillment system will optimize the retail store replenishment process for the grocery store chain. The robotic system will minimize the time to pick orders, ensure order accuracy for a wide range of order profiles, and reduce the reliance on the warehouse labor.

“Our new facility will be one of the most advanced distribution and logistics centers in South Australia and is a key part of our group’s vertical integration strategy within the supermarket sector,” said Glenn Sutcliffe, Logistics Manager at Drakes Supermarkets. “The center will incorporate robotics as part of a wider high-tech warehouse optimization strategy.”

In 1974 Roger Drake purchased his first supermarket, A three-laned store named Jack & Jill’s which employed only four staff.

Today, Drakes Supermarkets is the largest independent grocery retailer in Australia and specialises in supermarket retailing. Operating in over 50 stores across South Australia and Queensland, the company now has an annual turnover in excess of $1 billion and employs over 5,500 staff nationally.

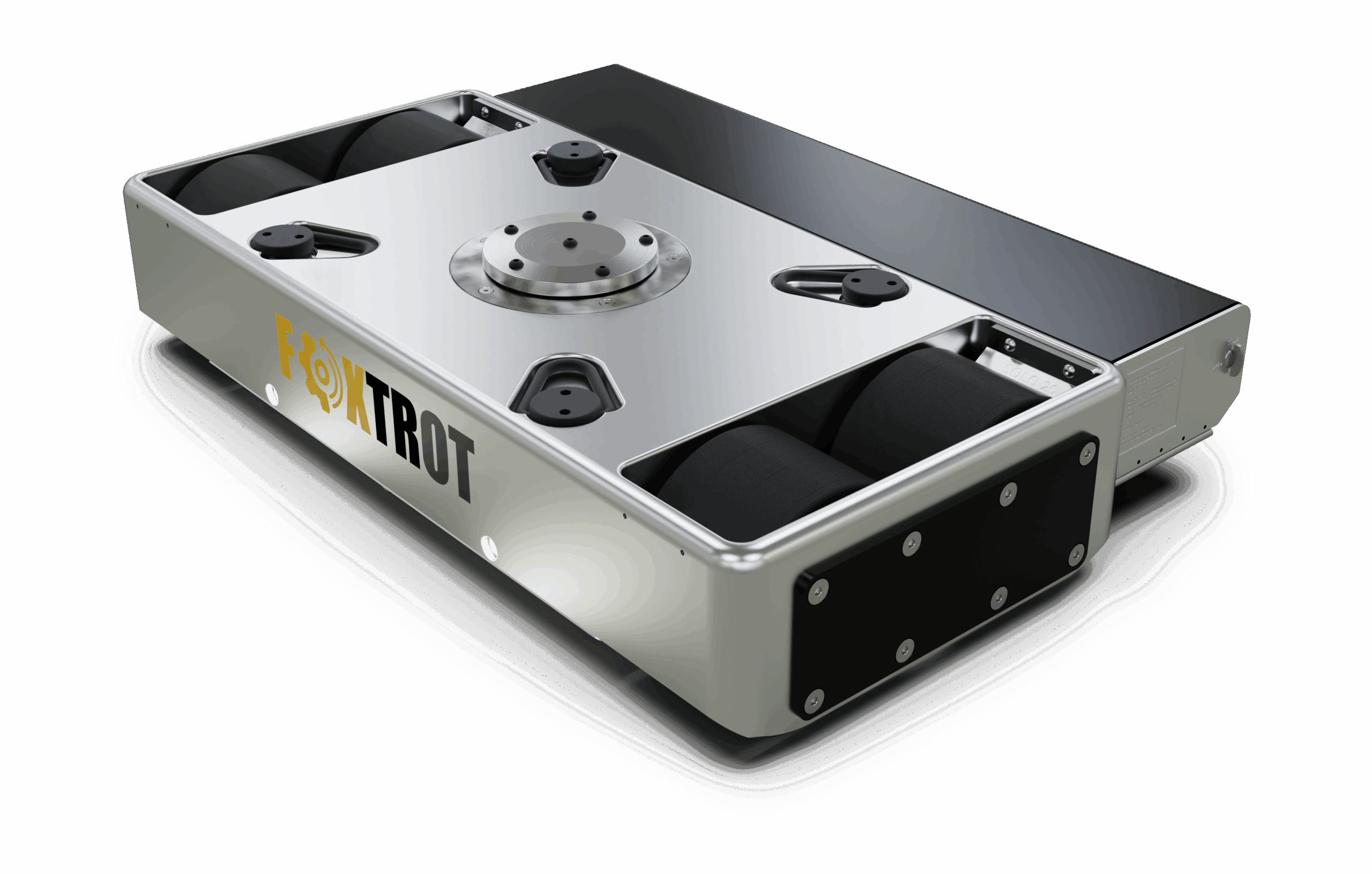

“Retail grocers, such as Drakes Supermarkets, are implementing robotic piece picking to automate the repetitive pick and place tasks that are labor intensive and difficult to staff,” said Crystal Parrott, Vice President, Robotics Center of Excellence, Dematic. “The Dematic Robotic Piece Picking Module, streamlines workflows through advanced technology and software. It can operate during multiple shifts per day with extraordinary accuracy while reducing operating costs and maximizing overall warehouse effectiveness.”

A Dematic RapidPICK Goods-to-Person (GTP) piece picking system will be implemented along with the robotic piece picking sub-system at the Drakes Supermarkets distribution and logistics center. In addition, the Dematic Multishuttle inventory storage, buffering and sequencing sub-system will perform as the pick engine for both goods-to-person and goods-to-robot piece picking.