Kalmar SmartPort for Chile Terminal

Kalmar, part of Cargotec, has received an order for Kalmar SmartPort process automation solutions from Terminal Graneles del Norte S.A. (TGN) for their greenfield terminal being built in Antofagasta region, city of Mejillones, Chile.

- The order was booked in Cargotec’s Q3 2021 order intake, and the operational go live of the system is estimated to be completed in Q4 2023.

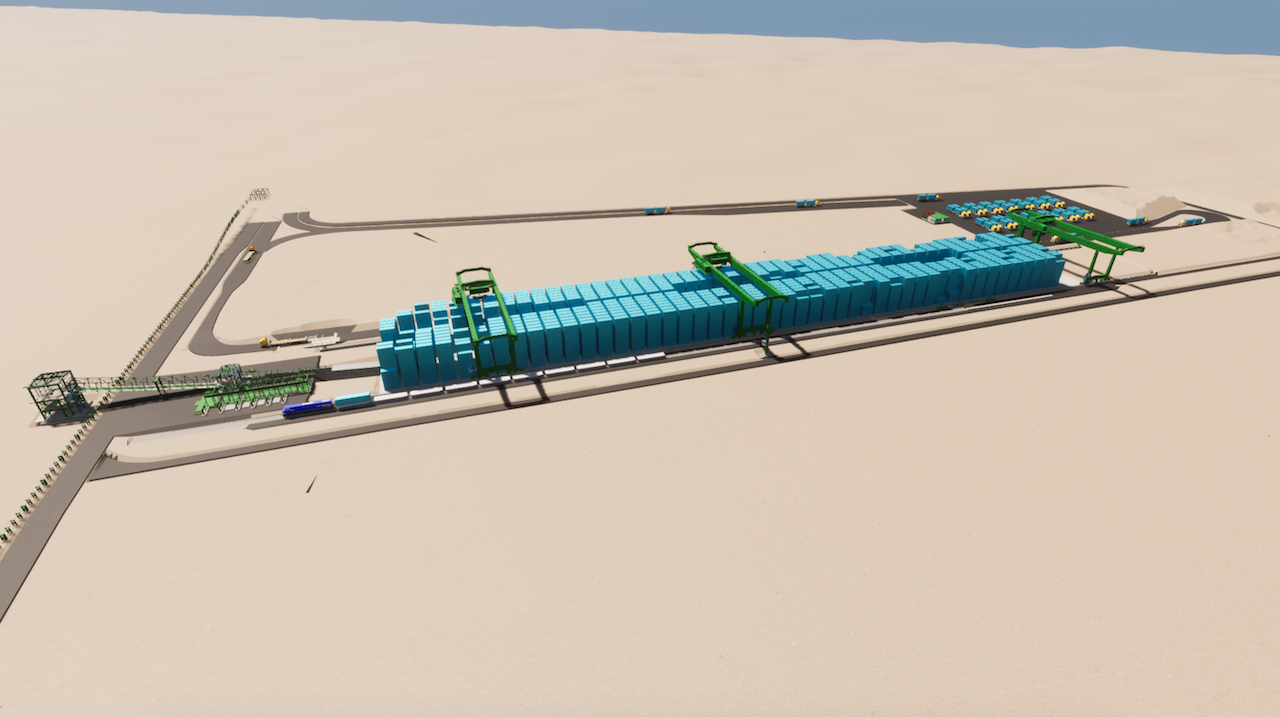

TGN operates a multi-purpose terminal in Mejillones Bay at the heart of Chile’s mining region, 1400 km from Santiago and 65 km from Antofagasta. To respond to the growing demand in the region, TGN is constructing a new container terminal in Antofagasta, which will feature an automated rail-mounted gantry crane system that will be enhanced with Kalmar SmartPort solutions to improve the efficiency and performance of the terminal.

After the go-live, the terminal will benefit from three Kalmar SmartPort solutions designed to improve efficiency, security and productivity:

- SmartMap, which enables real-time and historical visualisation of equipment location and container routing in the yard.

- SmartTrucks, which automatically tracks the road truck to ensure compliance with the work instruction and to increase crane productivity when the truck arrives at the point of work

- SmartLane, which will use RFID tags placed on a closed loop of containers to automatically register and track the containers as they enter or leave the terminal.

The SmartPort products will be fully integrated with the gate operating system and Navis N4 terminal operating system at the terminal.

TGN is constructing a new container terminal in Antofagasta, which will feature an automated rail-mounted gantry crane system that will be enhanced with Kalmar SmartPort solutions.

Eduardo Simian, Project Manager, TGN: “We chose Kalmar SmartPort solutions because of Kalmar’s ability to offer a solution that will be a key part of the automated container movement through the port. We are confident that the solution will help us ensure safe and efficient operations and fast truck turnaround times for our customers.”

Ezequiel Bracco, Sales Manager, Automation Solutions, Kalmar Americas: “We are pleased to welcome TGN as a Kalmar customer and help them achieve the highest level of productivity through our process automation solutions. With our help, the customer will be able to speed up their performance by minimising idle times and avoiding delays in their container yard with the best possible safety and security for their operational processes.”