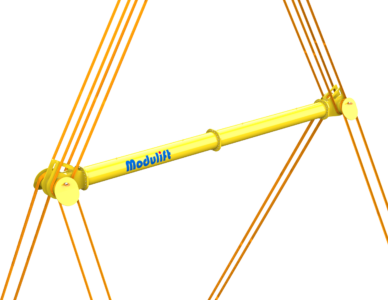

Adjustable Lifting Spreader Beam

Modulift has launched a combined lifting and spreader beam utilising a clamp system that provides a safe, fast and adjustable beam, enabling users to lift from multiple points top and bottom. The Adjustable Lifting / Spreader Beam (or MOD CLS) is stocked as a boxed product for immediate shipping and eliminates delays incurred waiting for alternative solutions, which often have to be manufactured to order.

The specialist manufacturer conceptualised the MOD CLS in response to demand from sectors where light industrial lifting scenarios inside or outside factory environments are commonplace. The fully adaptable system particularly lends itself to applications where flexibility and speed is key to productivity.

Sarah Spivey, managing director at Modulift, said: “The MOD CLS is game-changing from a lead-time perspective as users no longer have to wait for beams to be built. The launch is yet another example of Modulift responding to industry demand and providing distributors with a revolutionary, off-the-shelf, below-the-hook solution.”

The beam is being introduced in one size of up to 8.5t capacity, depending on configuration, but offered with four clamps as standard to adjust the lifting points to enable flexibility between a single top lifting point (lifting beam) or double top lifting points (spreader beam).

The clamps are pre-assembled on the beam together with markers to show alignment and the centre of lift. Clamps on the upper / top side of the beam are of a larger rating and size than the two clamps fitted to the bottom / underside of the beam. The MOD CLS can also be adapted to suit with up to an additional four clamps on the bottom side of the beam allowing users the flexibility of additional lifting points. If more points are needed, the flexible system can also be designed as a H-Frame, providing infinite lifting points.

Users can amend the lifting points between a single or a double point lift at the top.

Ian Locke, senior design engineer at Modulift, said: “Despite a host of individual component features, the product stands out as an entire lifting system, not just a spreader, lifting beam or clamp. This is where we differentiate ourselves from existing products in the marketplace. Rather than releasing the clamp design on its own, we set out to create a complete below-the-hook solution.”

However, Locke singled out the product’s reversible lug plate that grips onto the spreader when a load is applied. For additional safety, he said, there are two tightening screws / bolts at both ends of each clamp, allowing the user to apply a small pre-load to the clamp in order to keep it locked in position before the main load to be lifted is applied.

The clamps are pre-assembled on the beam together with markers to show alignment and the centre of lift.

The product represents further diversification of a portfolio that recently welcomed an innovative new end unit system with an integrated load cell (Active Link). Locke said: “Although the design fully reflects Modulift’s core design principles of providing customers with both flexible and adaptable solutions, there is nothing similar in our existing product range and it therefore represents another dimension to the range that our distributors have found hugely exciting.”

The product’s launch marks completion of extensive research and development that started over two year ago. The MOD CLS will be manufactured to a minimum stock level to facilitate next day availability as an off-the-shelf product for Modulift’s global distribution network, while plans are already afoot to offer another model with a higher working load limit (WLL).

A reversible lug plate grips onto the spreader when a load is applied.