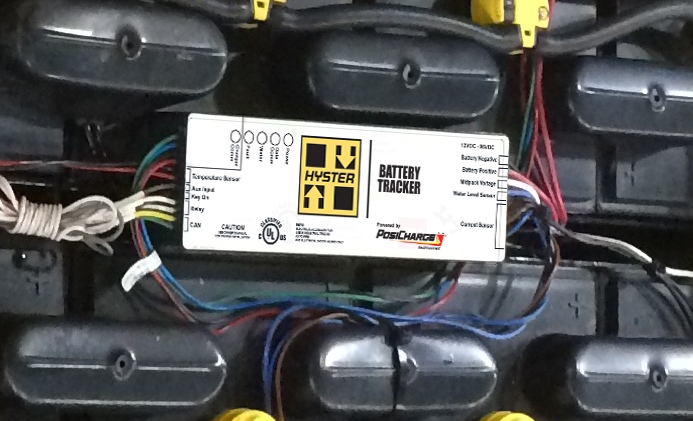

Battery Tracker with Powered by PosiCharge Technology

Hyster Battery Tracker with Powered by PosiCharge technology is a new battery management solution that monitors battery health and usage to help ensure proper maintenance and warranty compliance tracking.

Installed in as little as 20 minutes, the low-profile device stays with the battery during its lifetime and uses cellular communications to deliver actionable, real-time data on key performance metrics like state-of-charge (SOC), water levels, voltage current and temperature. Email notifications quickly alert fleet managers to potential battery issues that may affect equipment performance and uptime.

Data is only as good as the tools available to analyze it. Hyster Battery Tracker comes with a robust, back-office reporting suite that transforms the continuous 24/7 monitoring into easy-to-use reports and dashboards. Detailed daily tracking, weekly exceptions and lifetime statistical analysis reports provide instant visibility to battery health across the entire fleet, helping fleet managers identify potential issues before they become larger problems and simplifying warranty compliance.

Successful businesses need data-driven intelligence to guide decisions that improve efficiency and protect the bottom line. For lift truck fleets, devices like Hyster Battery Tracker can produce a wealth of relevant data insights for quick conversion into actionable business intelligence, allowing fleet managers to make timely, informed decisions. This helps eliminate potential battery-related downtime and improve internal battery maintenance procedures that can maximize battery life and reduce costs.

Installed in as little as 20 minutes, the low-profile device stays with the battery during its lifetime.

“An active fleet of lift trucks represents a significant investment and fleet managers are constantly on the lookout for unnoticed or undiagnosed needs that can lead to equipment downtime, performance setbacks and even operational and safety concerns,” said Pat DeSutter, vice president of fleet service and aftermarket for Hyster Company. “With Hyster Battery Tracker, fleet managers can finally get full visibility into their batteries, an integral, but largely unconsidered part of their operation and use that information to have more control over productivity and profitability.”