Cart with Tunneling AGV

Creform Corporation has introduced a cart with a tugger / tunneling style NSI AGV system for an automotive supplier of fabricated metal components.

The new system, consisting of six AGVs and six parts handling carts, are controlled by a Creform wireless traffic control system. Carts are assigned to a specific AGV and stay connected, however the AGV can be removed for service and the cart used manually. This new order is in addition to the 16 other various AGV units from Creform within the supplier’s operation.

The BST AGV Model, CA-A50060-NSI works as an automated tugger awaiting assignments. The customer’s manufacturing system accumulates calls for product from the plant floor and provides the AGV routing information through Creform’s traffic control system for the next available unit. There is an opportunity charging battery in the que area so system can run with minimal attention and interruption.

The typical AGV makes 20-30 trips a shift along a 1200 ft. route guided by a surface-mounted magnetic tape guidepath with RFID location tags. The unit operates two shifts and takes full bins of parts to the designated area where an associate removes the 15″ x 24″ bins and places empty bins on the cart for the return trip.

The Creform BST NSI AGV offers a sophisticated control system. It is programmable and can control 50 courses with up to 128 commands on each. Programs can be entered via HMI, USB memory, Ethernet cable or radio. The AGV unit features a Category 3 safety system with safety equipment that includes an audible warning device, flashing light, no- contact obstacle sensor (Laser Scanner) and E-stops. The unit runs on 24-volt power and can run a full shift prior to recharge or longer with opportunity charging.

The cart shown, with dimensions of 72″ L x 36″ W x 54″ T is built by Creform, utilizing its unique 42mm pipe and joint system. It is rated for a load capacity of 750 lb. The bins fit in four designated spots for secure transport and easy load/unload. The cart’s open design provides visibility thru the cart for personnel safety. The leading edge of AGV extends out from the front of the cart for easy access to the control panel.

The cart features four 5 in. dia. casters with urethane wheels for easy, stable, and safe rolling. The casters are ideal for the rigors of repeated towing by the AGV. All swivel for easy positioning in the manufacturing environment. The cart shown is built with Creform’s “white gray” plastic coated steel pipe.

Carts are available as a kit or an assembled structure or in the component form for a complete DIY solution. A variety of options include items such as hooks, label holders for shelf levels or even shelf positions, writing surface with clip boards, etc. A user can add a hitch to the cart and tow more than one at a time.

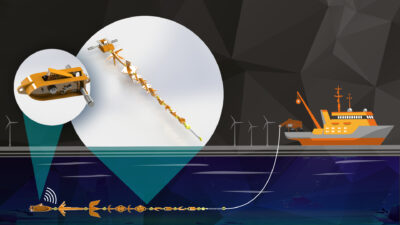

Creform cart with tunneling AGV.

The Creform system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and Lean Manufacturing programs. The company partners with customers in developing and implementing these programs.