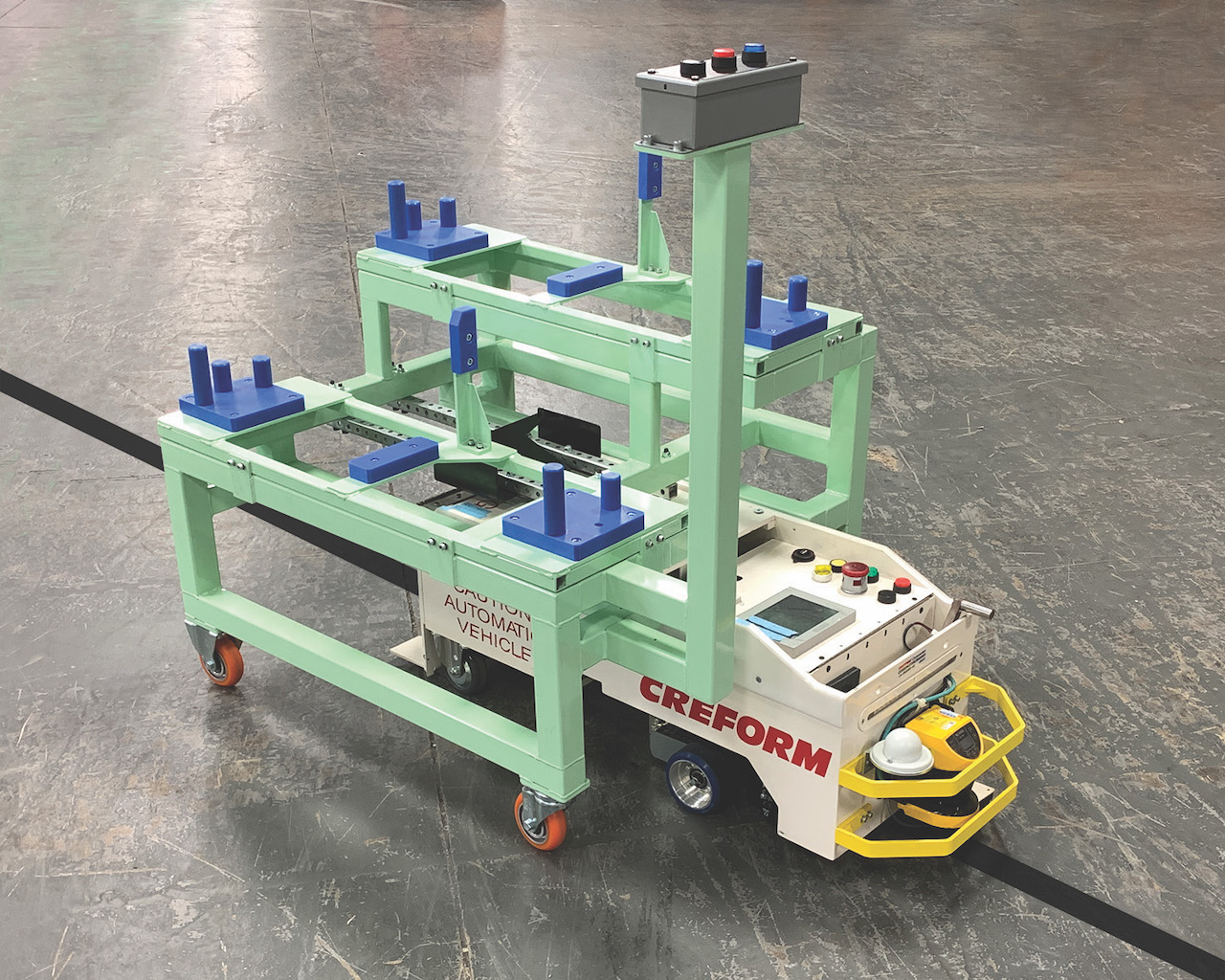

Creform Cart for Automotive Modules

Creform Corporation has designed and built a compact AGV with fabricated cart that provides a manufacturer with the ability to hold automotive front-end modules during assembly.

The Creform BST AGV, Model CA-250060-NSI-K9 works as an automated tugger, traveling along a magnetic tape guidepath, slipping under the stationary cart, extending a tow pin into the cart’s frame and then conveying it to a designated workstation or unload point.

This unit has the functionality of a larger Creform BST-NSI, but in a compact package for enhanced maneuverability. The AGV offers a sophisticated programmable control system and can control 50 courses with up to 128 commands for each. Course programming can be accomplished with a PC or HMI touch screen and programs can be downloaded via USB memory, ethernet cable or RF.

The AGV is powered by a 24-volt system with two 12v AGM batteries. With an optional opportunity charging system that extends off the back as an add-on module, the system provides for an optical communication between the AGV and battery charging station. The vehicle pulls into charging position, signals its presence, lowers the charging probe to contact the conductor plates embedded in the floor and turns on the charger for a quick battery boost. With each circuit of the guidepath, batteries are automatically charged by just pulling into the charging station positioned along the route. No human intervention is necessary.

The unit features a removable cover for access to system components and the whole assembly tilts up for access to the battery compartment. With the opportunity charging system the need to access batteries should be infrequent.

Creform Model No. CA-250060-NSI-K9 AGV with fabricated cart.

The Category 2 safety features include: Audible warning and flashing light, obstacle sensor, non-contact laser bumper and emergency stop. Options to the system include remote start via data transmitter at home station, radio communications to integrate with a Creform traffic control system, as well as preventative maintenance program to ensure reliable operations.

In this application, the custom designed and fabricated front-end module cart holds automotive front end module assemblies. The cart stays with AGV in normal operation and makes up the assembly line as well as delivery AGV.

Since they stay connected, the cart features a remote start/stop/work complete button panel that plugs into the AGV. This provides the operator a convenient way to control the AGV without having to access the lower front control panel on the AGV itself. The cart’s dimensions are 3′ W x 4′ L x 42″ T and holds about 500 lb.

The system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and lean manufacturing programs. The company partners with customers in developing and implementing these programs.