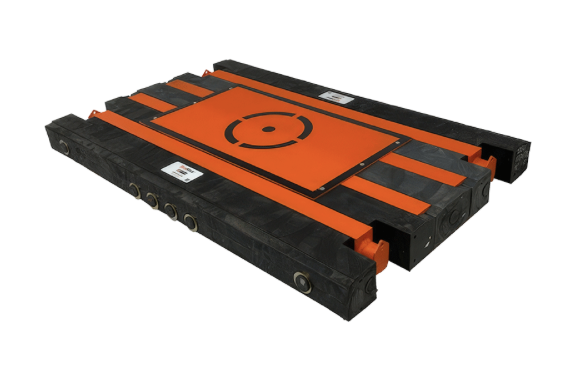

EcoMax Crane Pad

DICA, a provider of high-performance outrigger pads, cribbing and blocking and ground protection and site access products, announces EcoMax, a new crane pad.

Using a combination of steel and composite materials, crane operators can now take advantage of the benefits provided by both.

EcoMax delivers the same performance, durability, and longevity customers expect from DICA’s engineered products at a lower overall cost.

“EcoMax expands our crane pad line and fills a gap in the market,” said Kris Koberg, CEO of DICA. “It’s more durable and will last significantly longer than wood timber mats, and is a cost-effective alternative to steel crane mats and pads without sacrificing performance,” said Koberg.

EcoMax delivers the same performance, durability, and longevity customers expect from DICA’s engineered products at a lower overall cost.

EcoMax pads leverage the stiffness and strength of steel with the durability, longevity and lower cost recycled composite material resulting in maximized load distribution. The flanges of the I-beams engage the specially designed and molded composite timbers to create a single, rigid body that moves uniformly. This is different from traditional wood mats, where the timbers are held together with a through-bolt.

A center plate built into the pad creates a designated operating area to assist crane operators with outrigger float placement. This physical guide makes it easier to place the float for optimal load distribution, reducing setup time and improving safety on the job site.

EcoMax also features two distinct rating scenarios. The first is the standard rated capacity, which applies to conditions when the pad is fully supported. The second rating–referred to as the “Bridge Rating,” applies to situations where the ends of the pad are supported by the ground and a gap exists beneath the center.

“Materials should be in full contact with the supporting surface. However, we understand this is not always possible. EcoMax pads have the strength and stiffness properties to support loads without full contact with supporting materials, which enables EcoMax pads to be used in this de-rated scenario,” said Koberg.

Using a combination of steel and composite materials, crane operators can now take advantage of the benefits provided by both.

Additional practical features include built-in lifting lugs, which allow crews to safely lift individual pads or full stacks using standard synthetic wire rope or chain slings. To further enhance safety and functionality, the steel components are finished with a non-slip coating that improves the friction of the steel components.

The current EcoMax model is 24 sq. ft. and is rated for a maximum capacity of 160,000 lbs. (80 tons), making it ideal for cranes up to the 150-ton lifting class.

“EcoMax is about giving crane users more options. It offers the reliability and performance of an engineered product with a price point that makes sense for more customers,” said Koberg.