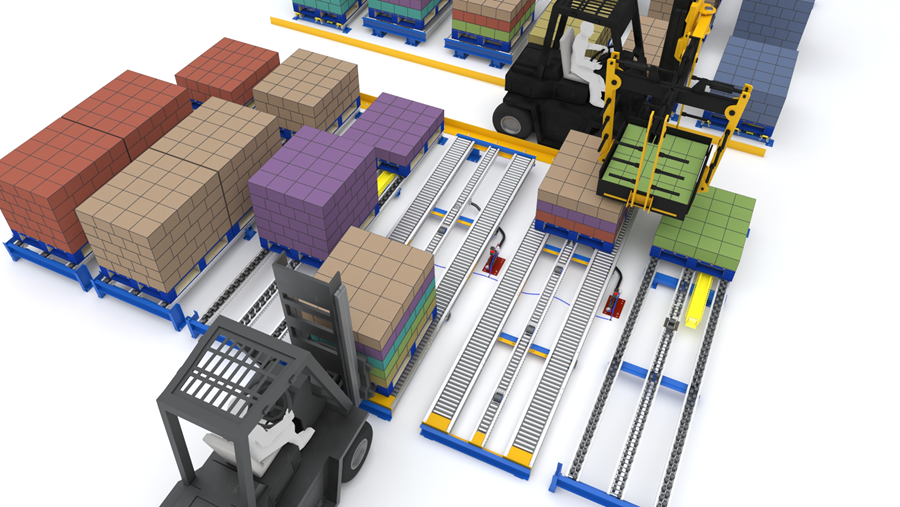

Ergo Build with Pallet Flow

Mallard Manufacturing, a gravity flow storage systems provider, has launched space and labor-saving layer pick solution for mixed-SKU pallet building—Ergo Build with pallet flow.

The Ergo-Build pneumatic pop-up separator holds the rainbow pallet in place at the pick aisle until the forklift operator presses the remote release button.

Unlike traditional layer pick applications, Mallard’s semi-automated Ergo Build lanes combined with pallet flow consolidates layer picking activity within a single aisle, boosting pick rates and safety while reducing downtime.

How it works

- Reverse flow lanes equipped with Ergo-Build pallet separators are interspersed with pallet flow lanes

- Pallet flow lanes feed pallets toward the layer pick aisle

- Forklifts (using layer pick attachment) pick carton layers to build rainbow pallets on the Ergo-Build lanes

- The Ergo-Build pneumatic pop-up separator holds the rainbow pallet in place at the pick aisle until the forklift operator presses the remote release button

- Once released, the complete rainbow pallet flows to the opposite aisle for pick up

“Ergo Build with pallet flow maximizes layer picking and mixed-SKU pallet building efficiency, delivering continuous productivity for facilities with high-volume order fulfillment. Since its release, we’ve already seen Ergo-Build transform pallet building in the beverage sector and we’re excited about the impact across grocery, automotive, and retail sectors,” said Kevin Risch, president, Mallard Manufacturing.

Ergo build advantages

- Significantly boost productivity

- Continuous workflow

- Remote-activated pneumatic controls

- Efficient extraction of completed pallets

- Safer work area

- 3-6 pallets deep