FlexQube, BlueBotics Combine on eQart

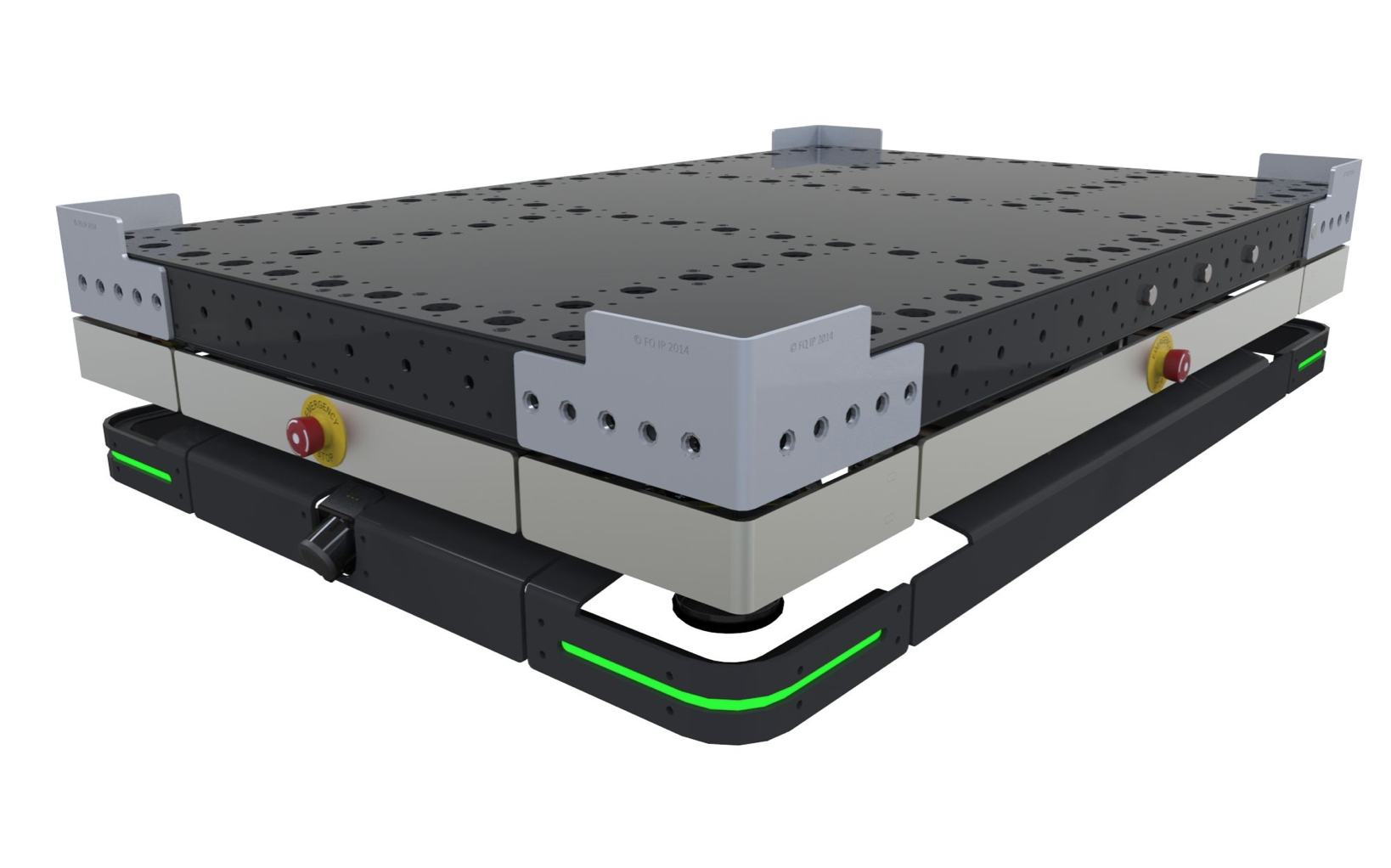

FlexQube has partnered with BlueBotics to integrate the Swiss company’s state-of-the-art autonomous navigation technology into its next generation of eQart. The eQart concept, launched in the fourth quarter 2019, is a customizable, smart, and motorized cart based on the patented FlexQube building block system.

By using natural, permanent features in the environment to navigate, the eQart will be able to navigate with high precision and robustness in dynamic and changing environments. The first eQart product integrated with BlueBotics’ ANT technology will be launched in the fourth quarter 2020 and with sales starting early 2021.

FlexQube CTO comments on the partnership: “We have been evaluating the BlueBotics ANT system for a while, and it is great to see that we now have reached a successful integration with our eQart robot platform,” says FlexQube CTO Per Augustsson.

“Going forward we can offer the eQart with an entirely natural navigation solution, which is a great complement to our vision-based line following navigation. It will enable the eQart to handle even more use cases at our customers and is aligned with our motorized cart vision. Partnering with BlueBotics enables us to reach the market faster with an experienced partner alongside our team, a partner whose navigation technology already drives more than 2,000 vehicles globally. This partnership also provides us with great new opportunities in terms of distribution and sales since there are numerous types of automated ANT driven vehicle available on the market, which makes it easy for potential customers to add new ANT driven vehicles to their fleets, like the eQart.”

The eQart concept, launched in the fourth quarter 2019, is a customizable, smart, and motorized cart based on the patented FlexQube building block system.

BlueBotics CEO comments on the partnership: “We are delighted to partner with FlexQube to help bring the new generation of eQart to life,” added Dr. Nicola Tomatis, the CEO of BlueBotics. “This intelligent, modular system is a game changer for customers with specific and evolving material handling needs. And the eQart’s flexibility mirrors that of our ANT technology, which requires no permanent on-site changes (no tape on the floor or reflectors for triangulation) and ensures accurate, repeatable vehicle operations time after time.”