Kinedyne Launches New Winches

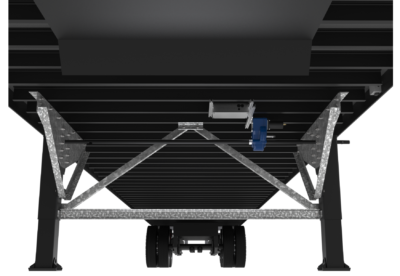

Kinedyne LLC, a manufacturer of cargo control technologies, including cargo securement, capacity and access solutions for the transportation industry, has introduced newly designed and engineered winches.

The new winches have a working load limit (WLL) of 6,670 pounds, more than 20 percent greater than the current industry standard of 5,500 pounds, and consistent with the 6,670-pound WLL of its RHINO MAX and K-FORCE winch straps. The move to the greater WLL means more secure loads, lower damage claims and other benefits.

Working as a load securement system, Kinedyne’s new winches and straps provide a greater WLL than many chain and binder systems. The company offers a wide variety of weld-on, portable, sliding, double “L” sliding and combination winch styles to ensure that the appropriate winch is available for each application.

“With the addition of our newly engineered winch designs, Kinedyne now offers a range of integrated cargo securement systems, all with an industry-leading WLL,” Bob Dissinger, director of U.S. sales for Kinedyne LLC, said. “In addition to making our winch offering stronger and more durable, we’ve reduced their weight by an average of 22 percent, making them easier to handle, and we’ve added a new “Thumb Saver” pawl that is simpler to operate, even with gloved hands.”

All of Kinedyne’s 3-bar winches have also been redesigned and feature the new “Thumb Saver” thumb pawl and increased spacing between bars from 0.75 inches to 1.13 inches. The unique 3-bar winch reel design allows for easy strap insertion, even when slots have ice buildup.

Kinedyne has engineered each new winch frame using heat-treated carbon steel, and the design includes a single piece rolled, heat-treated, split-mandrel with a welded cap and a forged steel thumb pawl. Most of Kinedyne’s popular winches have been converted to the new design, which features a black matte powder-coated finish.

Kinedyne’s new winches weigh less, offer a new thumb pawl feature and work with its RHINO MAX and K-FORCE load securement straps as an integrated system that boosts working load limits by more than 20 percent.

The new mandrel retains its optimized web-slot radius, which minimizes cutting and abrasion on webbing, thus extending its life. The material and design are also resistant to “egging,” or the elongation of the mandrel cap hole, which helps improve operator safety when using a winch bar.

Kinedyne engineers its winch components by attaching them to the frame using robotic welders to ensure manufacturing consistency. In addition, the manufacturing month and year are permanently stamped on each winch frame.

Slider winch frame thicknesses have been decreased to 7 millimeters, reducing their weight by 19 percent. While weld-on winch frame thicknesses remain at 8 millimeters, their weights have still been reduced by 25 percent, resulting in increased strength for both.

“We set a new industry standard for weight capacity with the introduction of our RHINO MAX and K-FORCE cargo securement straps in 2018,” Dissinger said. “With the introduction of our new winches, we’ve created a stronger, lighter-weight system that’s more durable, easier to operate and that fits a wide variety of cargo securement applications.”