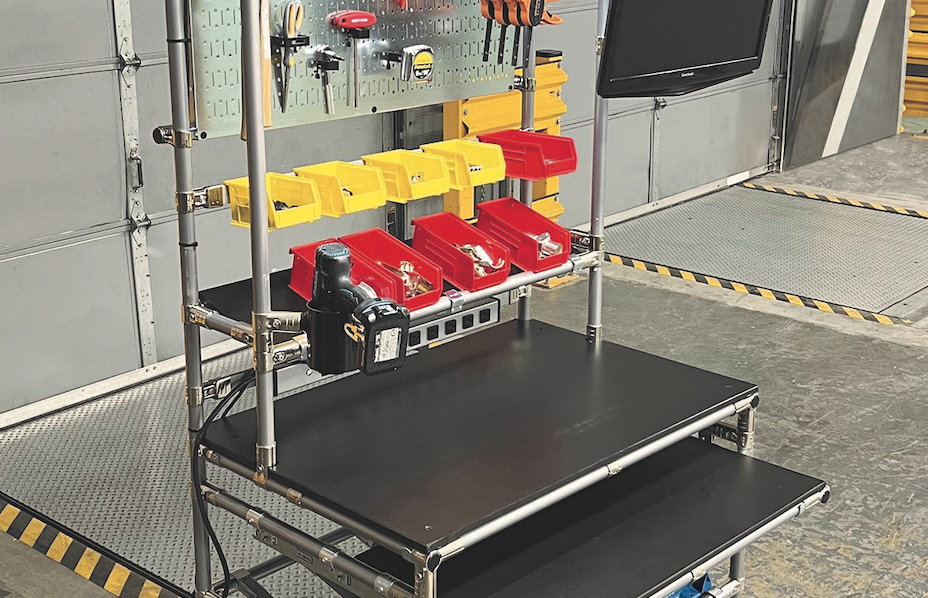

Medical Assembly Workstation

Creform Corporation has developed an assembly workstation for a medical component manufacturer. The workstation is set up in a straight-line configuration to support one-piece-flow assembly practices.

Due to the flexibility of the Creform system of pipe and joints, the custom configurable workstation with dimensions of 36″ W x 48″ L x 75″ H, allows the manufacturer to optimize its floor space. This flexibility makes it easy to add or remove associates as manufacturing needs change. The station could be run with one person or two if more production is needed. The structure has heavy duty leveling feet that adjust to the floor surface.

Creform 28 mm assembly workstation.

The unit features a plastic work surface as well as the pull-out sliding drawer just below the main work area, both made of HDPE plastic.

Above the work surface are two types of shelving for component storage. The lower shelf is an angled shelf built to provide flow for multiple boxes, while the upper shelf includes a Creform flat pipe mounted towards to front to enable plastic bins to hang. Also, the Creform flat pipe installed allows an eight-position power strip to be mounted to the unit.

The upper back section includes a steel pegboard for tool storage and provides for enhanced organization. At the top of the structure, a horizontal pipe is included to provide an LED work light. Also on the top, parallel Creform flat pipes are installed to allow a tool trolley to freely move left to right and allow a tool balancer to be connected.

Mounted on the right side of the structure is a monitor to display work instructions or product specifications. A tool holder is located on the front left to hold scanners or assembly tools.

Under the main work surface, there is an angled shelf utilizing Creform slide pipe for bin storage. Parts or supply replenishment can be performed on the back side of the structure preventing interruptions to the assembly operator working at the station.

Assembled structures are a great starting point for any user. After delivery and introduction, a user can take advantage of Creform’s flexibility by changing the station’s configuration and features to best match the needs of their production process and manufacturing associates.

The modular design allows a user to add only the accessories needed and configure the station that works best. Further, workstations can be mobile or stationary, come in various pipe colors and for even heavier duty applications they can be built using Creform’s unique 42mm pipe.

Useful accessories for such a station include additional flow lanes, drawers, information sheet holders, label holders, tool storage, and hooks to hang tools and supplies. All Creform workstations can be configured for ESD components when sensitive electronics need to be protected.

The unit features a plastic work surface as well as the pull-out sliding drawer just below the main work area.

Creform is the solution for dynamic material handling needs in the ever-evolving landscape of manufacturing.

As pioneers in adaptive systems, Creform empowers companies to seamlessly integrate continuous improvement methodologies like Kaizen, 5S, and lean manufacturing principles.

From pipe and joint structures to gravity roller conveyors and cutting-edge AGV technology, Creform helps optimize efficiency across various applications.

Whether it is streamlining workflow with flow racks and workstations or enhancing mobility with agile carts and AGVs, Creform solutions are tailored to elevate operational performance.