New Creform AGV

Creform Corporation has designed and built a new custom AGV system utilizing its bolt-on FH-B50066 bolt-on AGV drive bi-directional unit.

The system includes eleven AGVs used by the manufacturer to support its production line by acting as transfer vehicles between conveyors at multiple manufacturing points. It features two powered-conveyor deck for automatic load transfers, from both sides, of full and empty pallets between the various stations.

The AGV, with overall dimensions of 68″ L x 63″ W x 50″ T, features a conveyor height of 33 in. The unit can travel at speeds up 50 M/min and along an approximate 750 ft. long magnetic tape guide. Floor positioned RFID tags are used for the control of speed and obstacle sensor views. The bi-directional feature saves floor space by allowing the AGV to move back and forth on a single line path instead of a loop. It has a load capacity of 1455 lb. (660 kg).

Photocells on the AGV’s conveyor deck are used for load control functions and serve to verify that the load is secure during travel. Any load shift would be detected and will stop the AGV. Optical communication devices coordinate the conveyor operation between the AGV and stationary conveyor units. The AGV features radio communication to interface with traffic management system to keep the system moving efficiently.

Mechanical load safety stops rotate down when pulling into the conveyor stations to allow transfers. Gravity causes them to rotate back up when leaving the transfer point to ensure that the load is secure. Conveyor sections are covered to help keep loads clean while aboard, while removable and see-through panels provide access for maintenance.

The AGV features a heavy-duty fabricated steel base for strength and rigidity. Forklift tubes are integrated into the frame’s design which allows easy and safe lifting for maintenance.

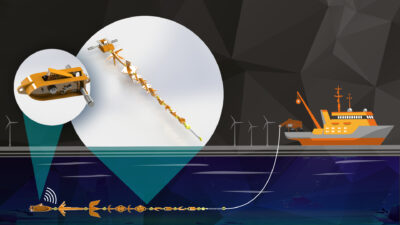

Creform AGV with dual conveyor decks.

The unit incorporates a 24-volt system, powered by two 12V AGM batteries with easy access at the center of the AGV. The opportunity charging system, activated by photocells, minimizes need for the user to manually change batteries. With each circuit of the guidepath, batteries are automatically charged by just pulling into the charging station positioned along the route. No human intervention is necessary.

Safety category 3 features on the AGV includes a safety circuit to cut power, audible warning device, flashing light, E-stops, LED band completely around the top of the AGV and a laser scanner on the front and back of the AGV. An HMI touch screen is used for user and maintenance interface with an operator screen positioned at the rear of the AGV.

The Creform system is used to create an array of material handling and efficiency enhancing devices and is a proven component in continuous improvement and Lean Manufacturing programs. The company partners with customers in developing and implementing these programs.