Overhead Crane Simulator Training

CM Labs Simulations, a provider of simulation-based training solutions in the construction, utilities, and ports markets, has expanded into the industrial market with the Intellia Overhead Crane Simulator Training Pack.

This advanced training pack incorporates multiple attachments, control schemes, and the exclusive capability to inject live faults into exercises, positioning it as a unique offering within the simulation training market.

While it is tailored primarily for steel producers and manufacturers, CM Labs can customize the training environment to suit a variety of industrial applications, enabling organizations to efficiently and safely train the next generation of operators.

The Intellia Overhead Crane Simulator Training Pack features exercises for different attachment types.

In response to industry demand for more effective training that closely mimics actual working conditions, the new pack includes precision training tools and exercises for handling typical loads found in steel manufacturing. Plans are underway to expand the range of attachments to further cater to diverse industrial needs.

“CM Labs is entering the industrial market to fill a critical need for advanced, realistic training solutions that ensure operators are fully prepared for the demands of real-world operations,” said Lisa Barbieri, VP of Marketing and Strategic Partnerships at CM Labs.

“With our proven track record in creating award-winning simulation-based training tools, we’ve developed a training pack and product line that addresses unmet training needs within the industry.”

While it is tailored primarily for steel producers and manufacturers, CM Labs can customize the training environment.

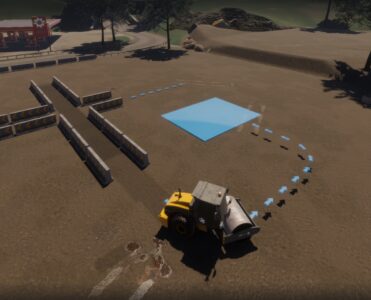

The Intellia Overhead Crane Simulator Training Pack features exercises for different attachment types, allowing operators to practice lifting a variety of steel products, including steel coils and steel slabs. These detailed exercises include rail cars and trucks in a realistic warehouse environment, for a virtual training experience that accurately reflects real work demands. The simulated overhead bridge crane also makes use of CM Labs’ renowned authentic machine behavior for an unrivaled level of realism, while four different control schemes provide added training flexibility.

“There’s no better way to train an operator than using a simulator, period,” said Jason Salmon,

Heavy Equipment Master Trainer at Gerdau, a leading steel producer that has integrated CM Labs’ simulation training solutions into its training program.

“It takes us about half as long to get somebody signed off on our equipment because once they hit the field, they already know how the machine works.”

When incorporated as part of CM Labs’ Intellia Intelligent Training System, the training pack offers instructors access to detailed data analytics and reporting features, as well as the ability to inject machine faults or distractions into exercises. These faults—such as attachment malfunctions, for example—allow trainers to prepare operators for unexpected challenges in a safe and stress-free way.

CM Labs Simulations, a provider of simulation-based training solutions in the construction, utilities, and ports markets, has expanded into the industrial market.

The Intellia Overhead Crane Simulator Training Pack joins CM Labs’ comprehensive catalog of heavy equipment training solutions, including its industrial manufacturing product line (Telehandler, Rough Terrain Crane, Crawler Crane, Tracked Excavator, Compact Track Loader, Forklift, and Forklift Safety+).

The Overhead Crane Simulator Training Pack runs on the following CM Labs equipment training hardware: Edge Plus, Edge Max, and Advantage. The Overhead Crane Simulator Training Pack is also compatible with the following controls: cobra joysticks, control lever box, pendant controls, and remote belly box (control lever box, pendant controls, and remote belly box only supported on Edge Plus and Advantage series simulators).

“We strive to help our clients cut training costs, shorten training times, and reduce the risk of a serious safety incident,” said Devon Van de Kletersteeg, Ports and Industrial Product Growth Manager at CM Labs.

“By designing longer, open-ended training scenarios in realistic virtual environments with multiple attachments and control schemes, we provide training exercises that are as close to the real thing as a simulation can get.”