Straightpoint Load Cells Lift Students’ Knowledge in Rigging Training

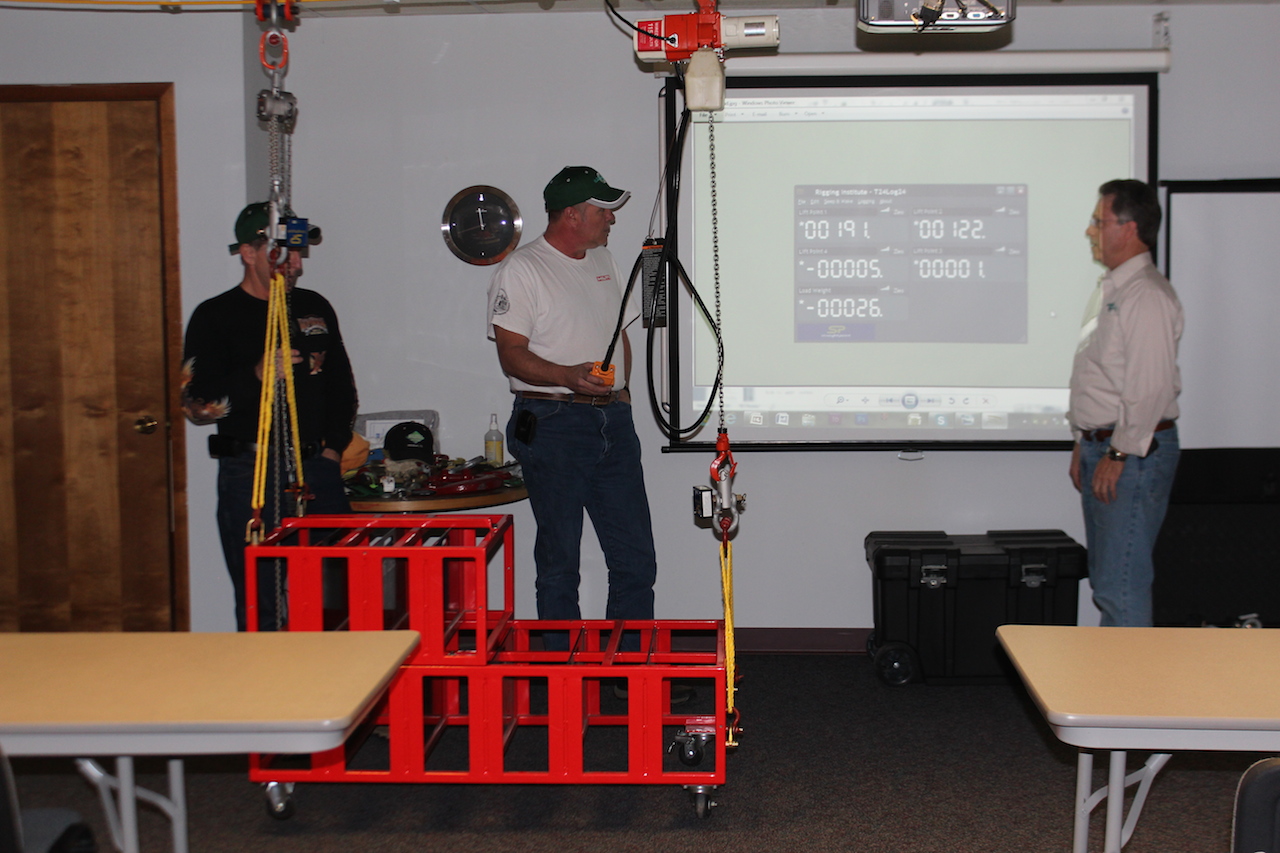

Straightpoint Inc. load cells are being used by rigging application and inspection training company the Rigging Institute to improve students’ understanding of the behavior of loads, slings, shackles and other rigging equipment in dynamic lifting situations.

Force measurement, load monitoring and suspended weighing load cell specialist Straightpoint manufactures equipment capable of providing dynamic information about lifting and rigging activity wirelessly, straight to a PC. It is a capability that has been seized upon by the Rigging Institute as it looks to drive the cultural improvement of U.S. lifting and rigging activity.

Lifting equipment rarely makes direct contact with a load, meaning lifting operations are only ever as safe as the attachment between the load and the crane and the rigger making that connection. As a rigger is generally the responsible decision maker for a lift, it is a sector that demands continued improvement of best practice.

The Rigging Institute has a variety of Straightpoint equipment, including two sets of five shackle load cells, utilizing Straightpoint’s wireless software system; and four load link digital dynamometer tension load cells, which is uses to demonstrate sling tension, dynamic loading and load sharing reality during load movement.

Mike Riggs, the president of the Rigging Institute, explained that Straightpoint’s equipment is contributing to a culture change that will enhance the safety and efficiency of rigging operations across North America.

He said: “Riggers are often not engineers or the academic type of person. Their personality type is to get the job done and, like me, can be skeptic to the math and recommendations from engineering and management departments. However, when they see these concepts presented by the load cells in front of their very eyes, a confidence is developed in the engineering end of the rigging task and team work between management, engineering and the worker begins to take hold.”

The Rigging Institute’s training courses are varied in type and length depending on customers’ requirements. Riggs said: “About 70% of the time we are introducing the concept of load cells and 30% of the time we are reinforcing the knowledge as well as new applications in the field for unique lifting activity. When my students see the load cells it is almost as though lights come on in their minds; they can verify that the math works and they can take ownership of their rigging activity, making them better lifting professionals.”

Riggs approached straightpoint two-and-a-half years ago having identified this gap in the industry’s knowledge. He conducted the first rigging class using load cells in 2013, using an L-shaped load with weights inside to simulate the irregularities of loads experienced in the field.

He said: “Students can be really shocked because it doesn’t gross metrically. Once we pass the 30-degree sling angle, the wireless readings really change appreciably. The load cells are setup to recalculate every second within two pounds which gives students a really clear picture of dynamic load activity.”