Whiting Completes Crane Upgrade at Tulsa Port of Catoosa

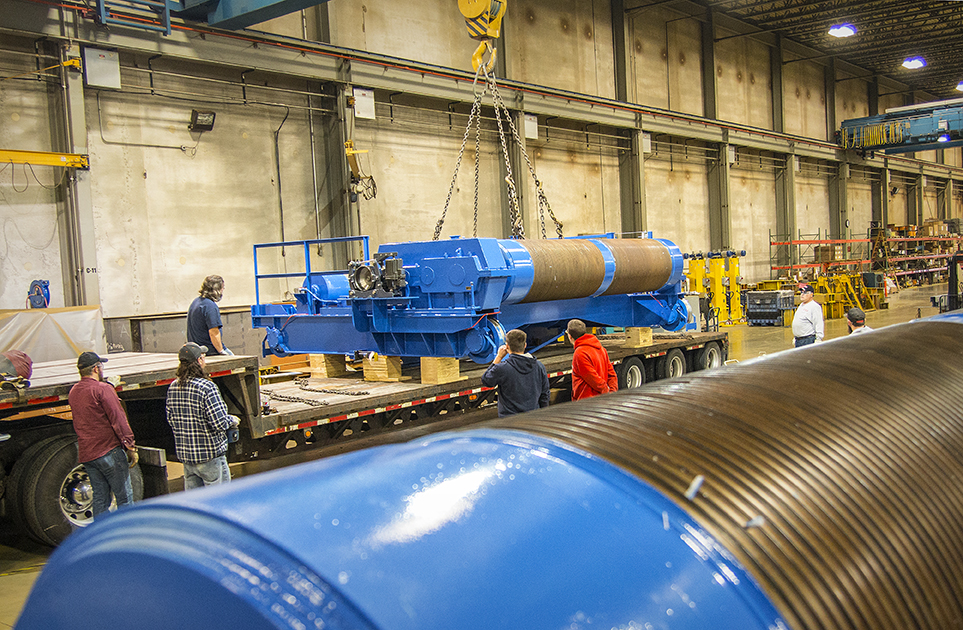

A total refurbishment and transplant of technology into the 200-ton crane at the heart of operations of the Tulsa Port of Catoosa helped the major inland U.S. port to continue to serve its existing users cost-efficiently while introducing radically expanded logistics capabilities for the future.

The Oklahoma Port, which typically handles more than 2.7 million tons of freight a year, is a major road, rail, and river intermodal shipping complex for U.S. and global companies, particularly those involved in agriculture, including wheat; steel; oil and industrial gas; mining products; and manufactured consumer goods.

Tulsa Port of Catoosa

The port is served by a sophisticated multi-hoist 200-ton bridge crane which had to be totally stripped and renovated. To ensure top performance and reliability, Whiting Corporation was selected to modernize the crane to the highest standards of safety and reliability as the centerpiece of the new port facilities created by the port over the last two years, including a new 720-ton dock on which the crane is located and 6,000 track feet (1,829m) of new rail.

Refurbishment of the crane was preferred to building a new one because of the time and expense involved.

Swift and thorough renewal of the crane was critical because port authorities expect the completion of expansion of the Panama Canal this year will provide new opportunities for container cargo to be delivered to the Port of New Orleans and onwards into the country’s inland waterway systems, of which the Tulsa Port of Catoosa is a major part.

Swift and thorough renewal of the crane was critical.

Working closely with port staff, Whiting Services put in 46 consecutive 10-12 hour days to complete the modernization project safely and on-time.

The versatile 100 ft. span double girder refurbished crane features two trolleys that each have a main and auxiliary hoist: one with a capacity of 100 ton / 50 ton and the other with a capacity of 100 ton / 40 ton. With lifting heights of over 90 ft., the crane is integral to tasks such as loading barges that can hold as many as 15 rail cars or 60 truckloads of cargo for maximum cost efficiency and minimal environmental impact.

In 46 consecutive field days at Tulsa Port of Catoosa, Whiting and Whiting Services took down the old crane; sandblasted, repaired and repainted the few structures remaining on-site; and installed all the new components.

Freight moves through the port using barge, rail and truck, often in combination, employing transportation assets such as the docks, terminals and the 1.5 mile (2.4km) channel on which they are located. Shippers are now able to load barges directly onto rail or truck, or effectively trans-load between truck and rail, creating a seamless and cost-effective logistics operation for companies ranging from break bulk to manufactured project cargo.

Whiting Corporation was selected to modernize the crane to the highest standards of safety and reliability.

Refurbishment of the crane was preferred to building a new one because of the time and expense involved in constructing a totally new crane with all the features and versatility already contained within the structure of the original purpose-built crane.

A total refurbishment and transplant of technology was required.

“Customers and stakeholders of the port won both ways through the decision to cost-efficiently rebuild at a substantial saving on the cost of a new design, while also benefitting from the introduction of the latest safety and logistics technologies on the refurbished crane,” said Scott Bort, senior industrial marketing strategist, Whiting Corporation.

“The project was a masterpiece of partnership and planning between Whiting’s crane specialists and a port management team (reporting to Bob Portiss, port director for the City of Tulsa Rogers County Port Authority) who oversaw the port upgrade of which the crane refurbishment is an integral part. Work was completed late last year after two years of carefully phased construction.

Working closely with port staff, Whiting Services put in 46 consecutive 10-12 hour days.

“We had to do our work as quickly and efficiently as possible to fit within the narrow time frame to bring the crane back online while Tulsa Port of Catoosa continued to serve the 2,500-acre (8km2) complex,” said Bort.

The complex already serves more than 70 companies, employing more than 3,000 people and contributing more than $300 million to the local economy. Global and national brands using the facility include ArcelorMittal shipping and mining products, Gavilon fertilizers, Linde engineering, Matrix tanks for the oil and gas industries and Safety-Kleen environmental services.

The port is served by a sophisticated multi-hoist 200-ton bridge crane which had to be totally stripped and renovated.

The crane upgrade—a multi-dimensional jigsaw of phased tasks fitting around minimization of customer inconvenience—involved the Whiting team working with port staff while supported by the full engineering and manufacturing resources of the Whiting Corporation, a leading crane manufacturer and lifting equipment service organization, as well as being an authority on safe lifting. Whiting supplies diverse industries where safety and reliability are critical, including shipping, railway, aerospace, car and general manufacturing, and power generation, including nuclear power.

‘We had to do our work as quickly and efficiently as possible to fit within the narrow time frame to bring the crane back online’ – Scott Bort, senior industrial marketing strategist, Whiting Corporation.

In 46 consecutive field days at Tulsa Port of Catoosa, Whiting and Whiting Services took down the old crane; sandblasted, repaired and repainted the few structures remaining on-site; and installed all the new components on machinery both on-site and off-site, in the lay down working area.

“We basically replaced everything but the existing girders, part of the end trucks, the runway and runway structure. What we didn’t replace, we repaired, prepped, primed, and painted for ongoing durability,” said Bort.